Since electric motors are a common and essential part of our lives, we tend to ignore the complexities of engineering that are used to create, design, and manufacture these reliable devices. One of the central parts of an electric motor is the stator. As the name implies, a stator is a static part of a motor whose purpose is to create a magnetic field. Read More…

We are proud of the craftsmanship of our engineers. All of our products are made right here in the United States and we promise that these items are created from high quality resources. Our electrical coils are unique and efficient.

Established in 1973, Classic Coil Company is a Contract Manufacturer of electronic coils. We manufacture coils for a variety of industries; winding wire gauges from 4-58 AWG. We are ISO 9001-2015 certified, ITAR registered and DFARS Compliant. Our Engineering services allow us to assist with design, reduce cost, and increase efficiency in production. Call or visit our website to learn more about...

Since 1962, Torelco has been a supplier of electric coils and transformers of superior quality. We offer custom coils, solenoid coils, ferrite core coils & toroid wound coils to serve a range of industries. Markets served include medical, military, electronics, and industrial. When you work with us, our promise is to build to the exact specifications and meet the custom needs of our customers.

Check out what’s new online at Precision Econowind, manufacturer of the highest quality custom coils at reasonable prices, with on time delivery. Serving the coil industry for over 30 years, we’re experienced with producing loudspeaker & medical industry coils, coils wound on customers’ bobbins/tooling; freestanding, flat wire, edge wound, square, rectangle & shaped coils. Submit your specs ...

Triad Magnetics has been in the electric coils industry for over 75 years. Giving us the knowledge and expertise to be one of the best in the industry. We have a wide range of electric coils and inductors as well as the ability to custom engineer and manufacture electric coils to our customer’s needs. Having served the needs of many industries for more than half a century, Triad believes its...

More Stator Coil Manufacturers

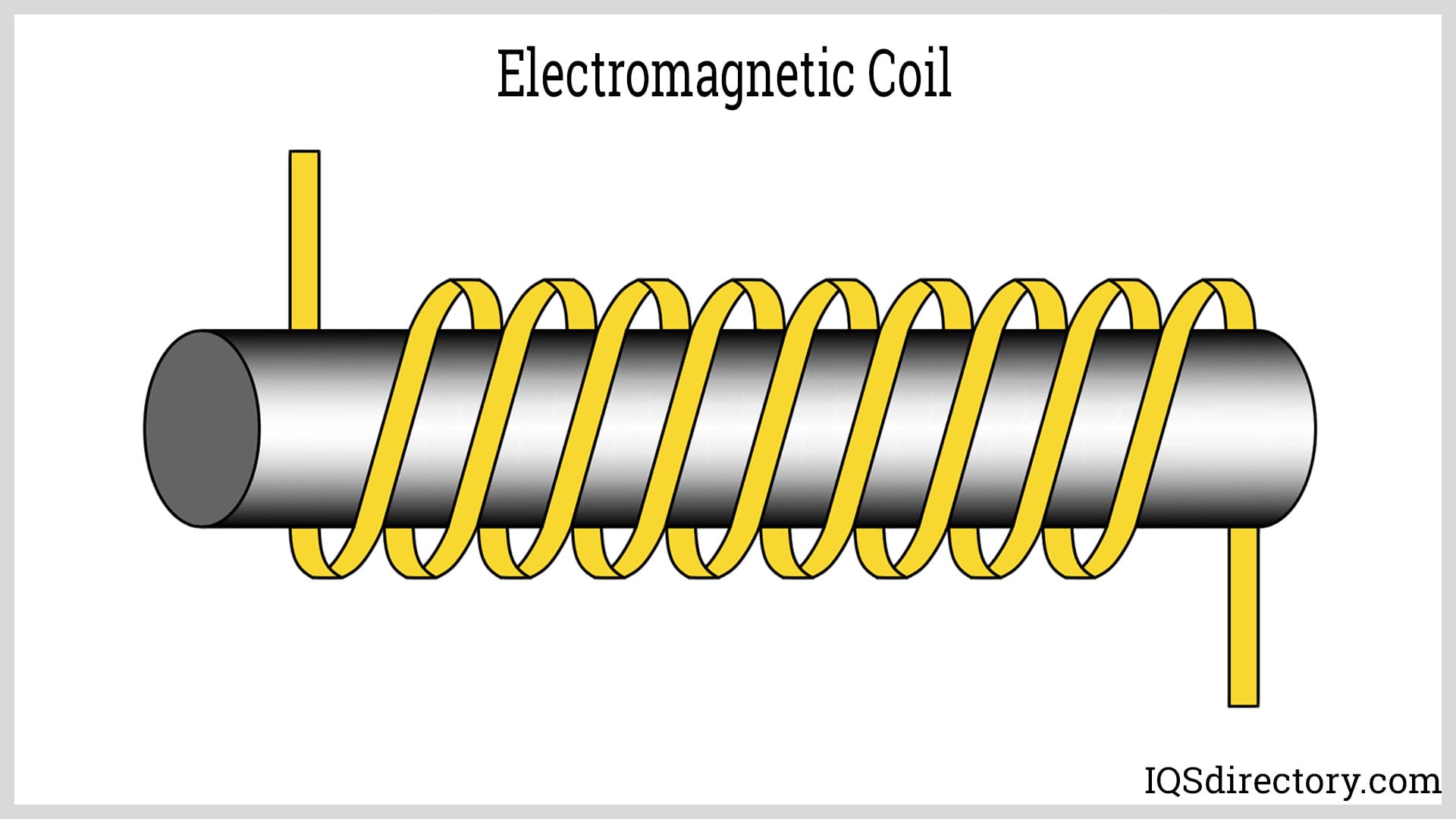

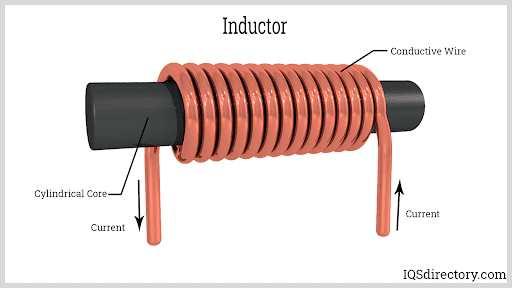

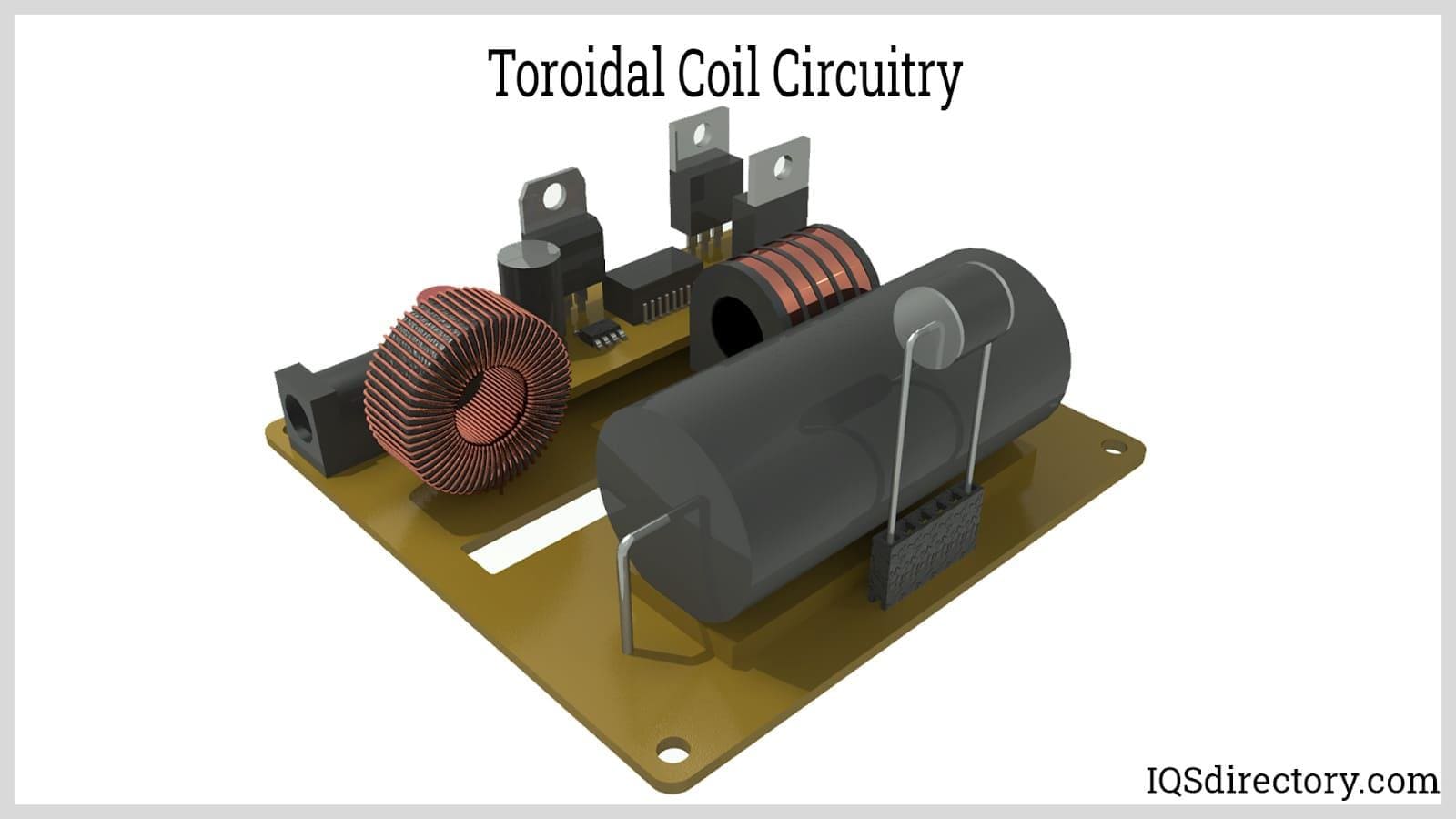

When electricity is passed through a wire, a magnetic field is created. To enhance the magnetic field generated by the passage of current, the wires are wrapped around to form a coil. This is the simple explanation of the design of a stator, which consists of wires that are wrapped on top of one another to form a coil.

Unlike an electric coil, stator coils do not have a core but surround a rotor. In a simple motor, electric current passes through the stator that creates an electromagnetic field that turns the rotor to produce mechanical energy.

What is a Stator?

A stator consists of a core, frame, and winding, with the core as a means of supporting and protecting the three-phase wire winding. The key factor in a motor is the interaction between the stator and rotor. When electric current is passed through the stator, an electromagnetic field (EMF) is creating that turns the rotor. It is the interaction between the rotor and stator that produces the power for the motor.

Stator Coil Materials –

Though there are many forms of wire, copper is always the first choice for the creation of electronic devices. This especially true in the case of the construction of stator coils. The materials used in the production of a stator are copper wire, iron, and steel or aluminum for the housing. Iron is chosen as part of a stator for the efficient way that it produces electric flux, a measure of the strength of an electric field.

Copper wire is an essential part of all electric devices for its conductivity, ductility, and high melting point. In a stator, the wire is coated with lacquer, or laminated, to increase its density. The wire is wound three times for a three-phase stator. The winding process has to be completed efficiently to ensure a high fill factor, which is influenced by the insulation of the wire and its coating. The higher the fill factor, the motor efficient will be the performance of the stator.

Stator Applications –

Years ago, before the inception of alternators, automobiles required a generator to produce the spark to start. At the center of a generator was the stator coil that created a magnetic field that turned the rotor at the center of the generator. Even though the generator has been replaced by alternators, at the heart of an alternator is a stator coil. This is also true of a wide variety of motors from the fan on a computer to the huge turbines that produce large amounts of electrical power.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services