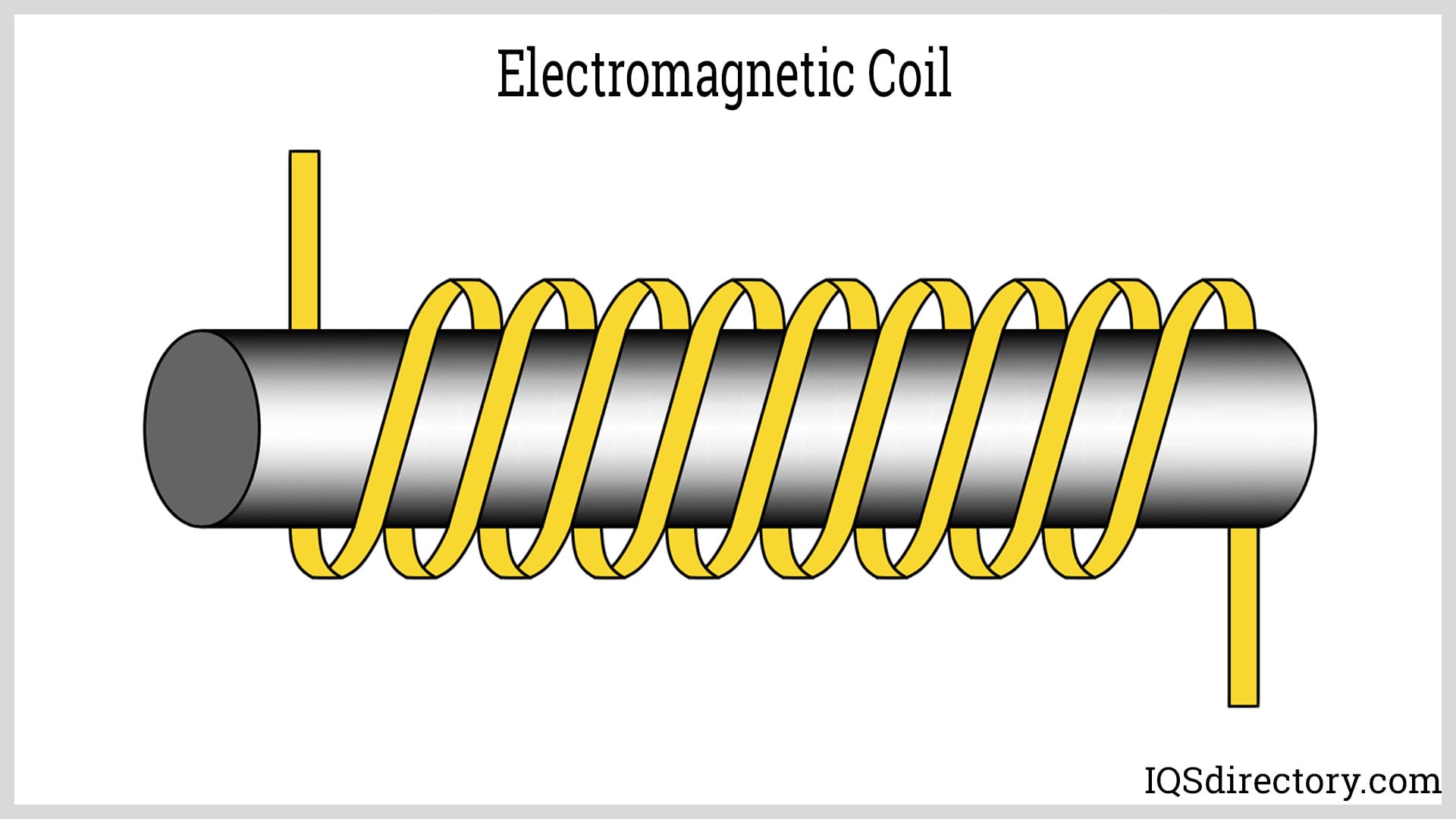

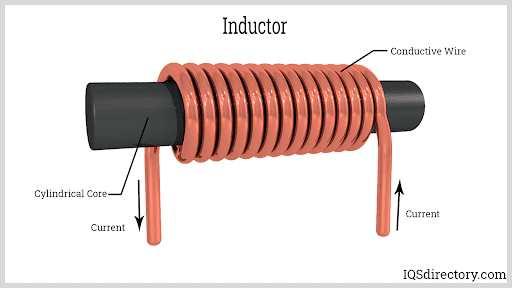

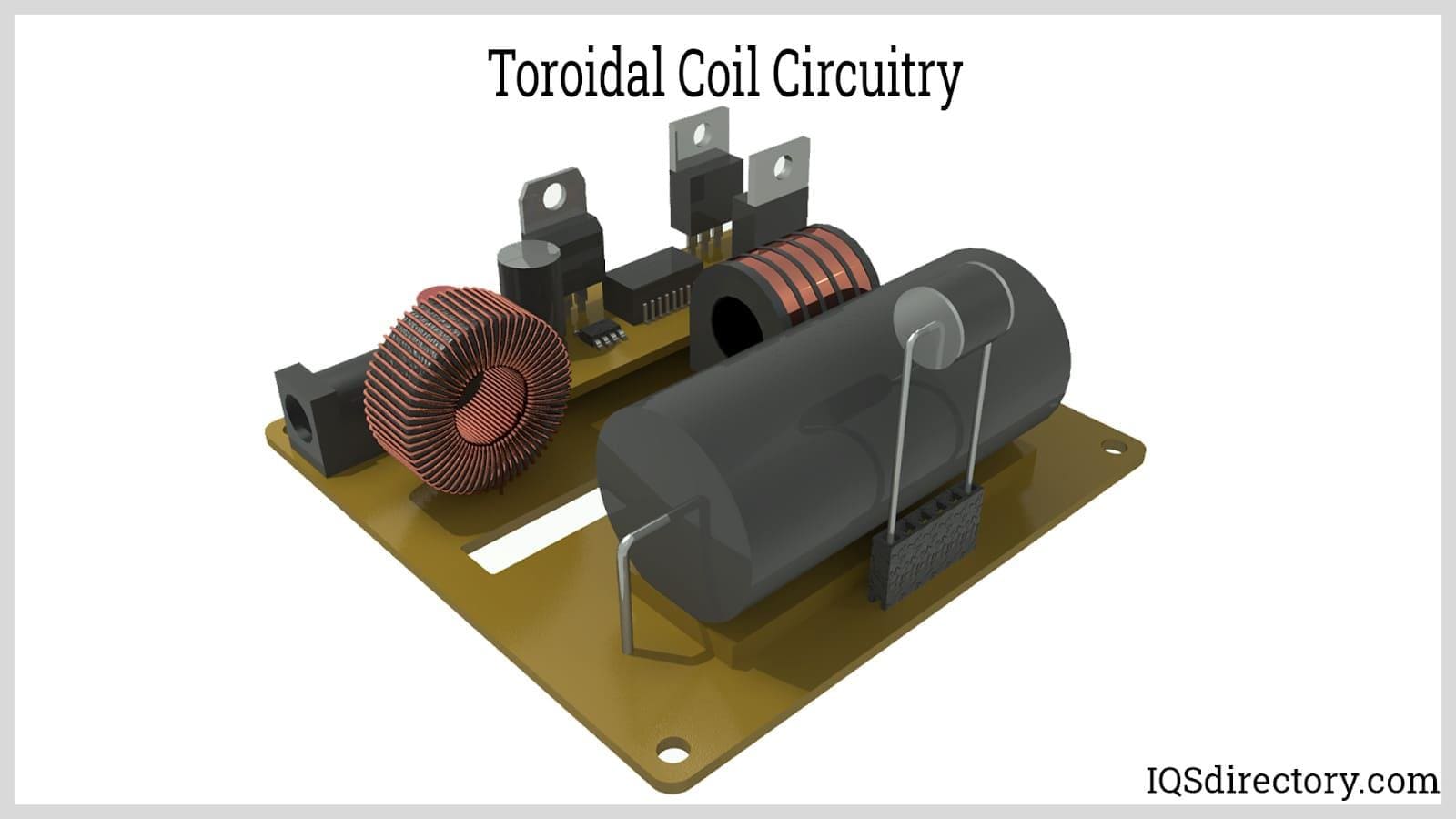

When we use an electric motor, we are actuating a set of factors that are designed to keep the motor running and ensure its performance. At the heart of any electric motor is an electric coil, which is a set of wires that have been tightly wound to form a cylinder. All electric motors have some type of coil. The design of the coil depends on the application and the needed current to run the motor. Read More…

We are proud of the craftsmanship of our engineers. All of our products are made right here in the United States and we promise that these items are created from high quality resources. Our electrical coils are unique and efficient.

Established in 1973, Classic Coil Company is a Contract Manufacturer of electronic coils. We manufacture coils for a variety of industries; winding wire gauges from 4-58 AWG. We are ISO 9001-2015 certified, ITAR registered and DFARS Compliant. Our Engineering services allow us to assist with design, reduce cost, and increase efficiency in production. Call or visit our website to learn more about...

Since 1962, Torelco has been a supplier of electric coils and transformers of superior quality. We offer custom coils, solenoid coils, ferrite core coils & toroid wound coils to serve a range of industries. Markets served include medical, military, electronics, and industrial. When you work with us, our promise is to build to the exact specifications and meet the custom needs of our customers.

Check out what’s new online at Precision Econowind, manufacturer of the highest quality custom coils at reasonable prices, with on time delivery. Serving the coil industry for over 30 years, we’re experienced with producing loudspeaker & medical industry coils, coils wound on customers’ bobbins/tooling; freestanding, flat wire, edge wound, square, rectangle & shaped coils. Submit your specs ...

Triad Magnetics has been in the electric coils industry for over 75 years. Giving us the knowledge and expertise to be one of the best in the industry. We have a wide range of electric coils and inductors as well as the ability to custom engineer and manufacture electric coils to our customer’s needs. Having served the needs of many industries for more than half a century, Triad believes its...

More Sealed Coil Manufacturers

Most motors are used in normal conditions at a factory, office, or home. Seldom do those motors have to face conditions that may damage the coil or interfere with the operation of the motor. There are circumstances when a coil may be faced with situations where it will have to endure a more aggressive and hostile atmosphere. Motors designed to operate in those conditions require an extra layer of protection to prevent them from failing. The type of coil designed to meet those kinds of applications is referred to as a sealed coil.

What is a Sealed Coil?

The name of a sealed coil is a full definition of what it is. Sealed coils are tightly wound insulated coils that have been treated with an extra layer of material as a form of protection. The manufacture of a sealed coil follows the normal process of winding and insulating. Once the coil has been completed, it is sealed with a type of material, which can be a polymer resin, epoxy, or silicone resin.

There are several reasons to seal a coil in an extra layer of protection. The most obvious reason is as a means of protection against the elements from damaging a coil and preventing it from performing properly. Moisture is one of the biggest concerns. The process of injecting a liquid material over a coil and baking it makes it impenetrable.

Another benefit of sealed coils is their ability to dissipate heat, a major factor in the deterioration of electronic devices. The tight-fitting seal is forty times more efficient at removing heat and keeping the coil cool.

Materials Used to Seal a Coil –

Some of the most common materials used to seal coils are chosen for their ability to adhere to the coil wires and fill in the gaps and empty spaces that are common to electrical coils. Some of the popular materials are polymer resin, silicone resin, and epoxy, with polymer resin being the most used.

Epoxy is one of the more sturdy and durable materials that has thermal stability and able to resist a wide variety of liquids and gases. When it is applied to a coil, it easily fills in the gaps and empty spaces to enhance the performance of the coil.

As with epoxy, polymer resin is an excellent sealing material with the added feature of being able to seal windings and laminations as a means of dampening noise and lessening the vibrations produced by spindles. A benefit of polymer resin is how it solidifies and becomes rigid after the curing process.

Silicon resin has all of the properties of polymer resin and epoxy with the additional ability to perform at a wide variety of temperatures. The process for applying silicon resin is to inject it into a coil.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services