Ignition coils are a crucial component in modern internal combustion engines, responsible for providing the necessary spark to ignite the fuel-air mixture. These coils work by converting the 12-volt battery voltage into the high-voltage electrical pulse necessary to create the spark. Read More…

We are proud of the craftsmanship of our engineers. All of our products are made right here in the United States and we promise that these items are created from high quality resources. Our electrical coils are unique and efficient.

Established in 1973, Classic Coil Company is a Contract Manufacturer of electronic coils. We manufacture coils for a variety of industries; winding wire gauges from 4-58 AWG. We are ISO 9001-2015 certified, ITAR registered and DFARS Compliant. Our Engineering services allow us to assist with design, reduce cost, and increase efficiency in production. Call or visit our website to learn more about...

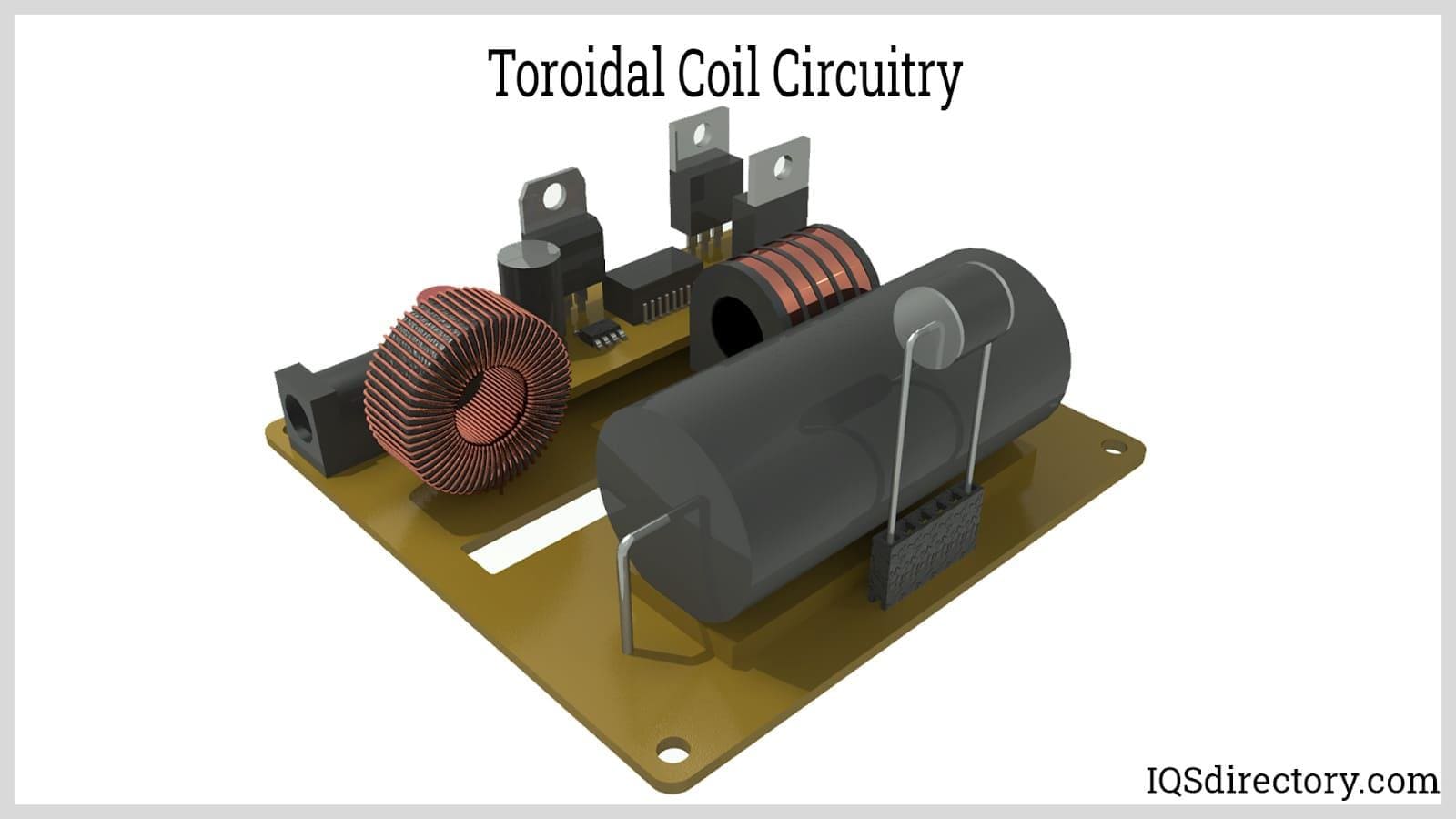

Since 1962, Torelco has been a supplier of electric coils and transformers of superior quality. We offer custom coils, solenoid coils, ferrite core coils & toroid wound coils to serve a range of industries. Markets served include medical, military, electronics, and industrial. When you work with us, our promise is to build to the exact specifications and meet the custom needs of our customers.

Check out what’s new online at Precision Econowind, manufacturer of the highest quality custom coils at reasonable prices, with on time delivery. Serving the coil industry for over 30 years, we’re experienced with producing loudspeaker & medical industry coils, coils wound on customers’ bobbins/tooling; freestanding, flat wire, edge wound, square, rectangle & shaped coils. Submit your specs ...

Triad Magnetics has been in the electric coils industry for over 75 years. Giving us the knowledge and expertise to be one of the best in the industry. We have a wide range of electric coils and inductors as well as the ability to custom engineer and manufacture electric coils to our customer’s needs. Having served the needs of many industries for more than half a century, Triad believes its...

More Ignition Coil Manufacturers

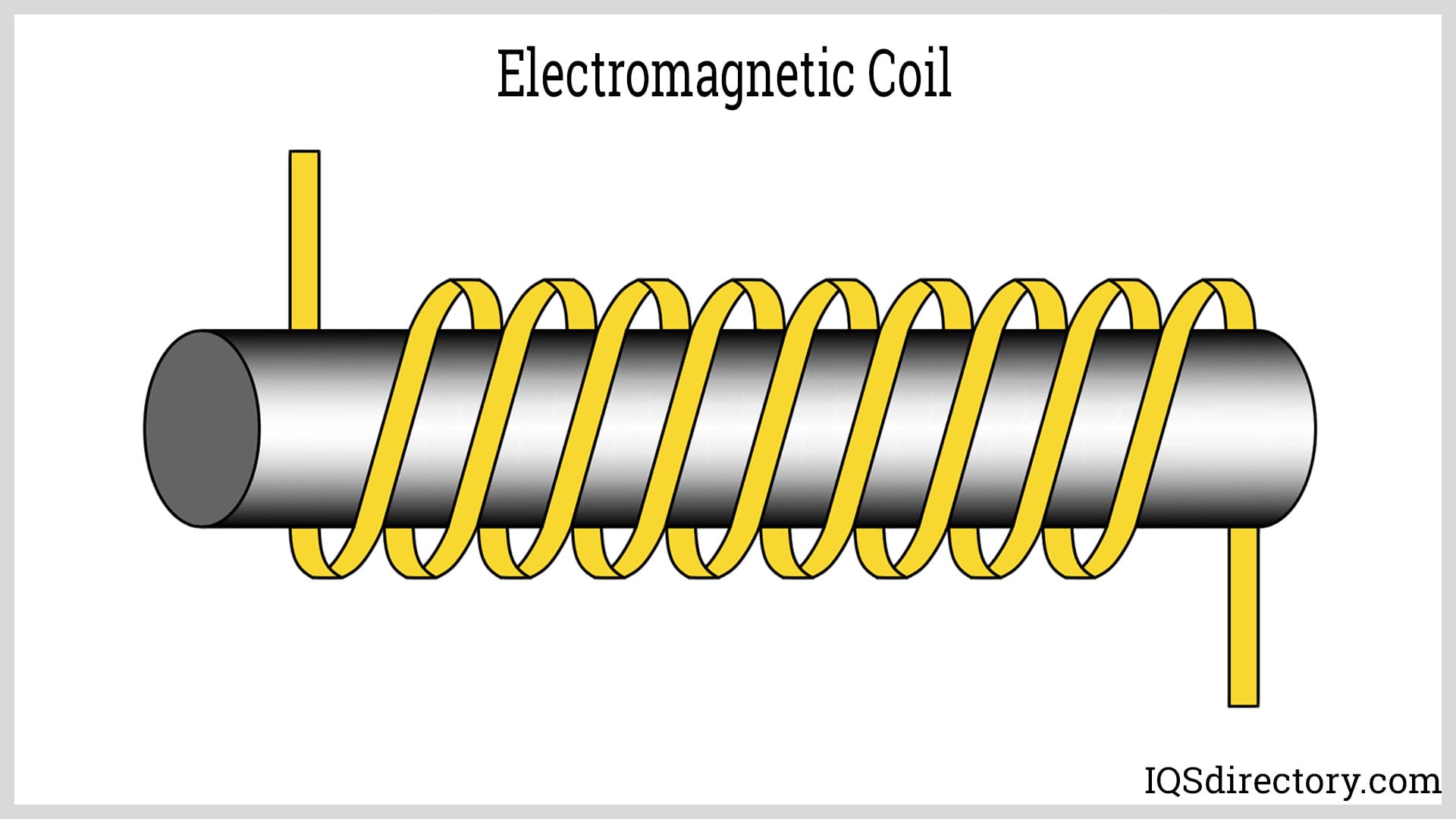

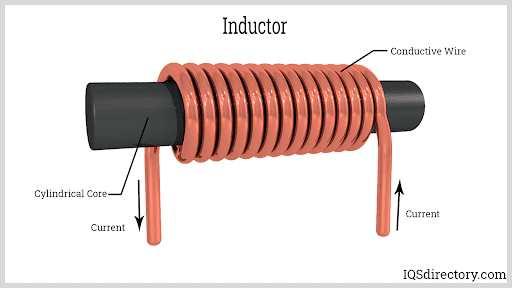

Components of an Ignition Coil

An ignition coil consists of four main components: the primary winding, secondary winding, iron core, and distributor. The primary winding is responsible for receiving power from the battery and generating a magnetic field around the iron core. This magnetic field is then transferred to the secondary winding, which has many more turns of wire than the primary winding. The secondary winding's role is to amplify the voltage generated by the primary winding, which results in a much higher voltage output that is necessary to create a spark at the spark plug. The iron core provides a path for the magnetic field to flow between the primary and secondary windings, which helps to maximize the transfer of energy between the two windings. Finally, the distributor is responsible for delivering the high-voltage pulse to the correct spark plug at the right time, which ensures that the fuel-air mixture is ignited at the right moment in the engine cycle.

Variations of Ignition Coils

There are several variations of ignition coils that differ in materials, components, and design. Some ignition coils are made of copper, while others use aluminum. Copper coils tend to be more expensive, but they also offer better conductivity and are more durable in high-performance vehicles. Ignition coils can also vary in the shape of the iron core and the size of the windings. These differences can impact the ignition coil's performance in racing engines, where high power output and quick spark delivery are critical. Some ignition coils, such as double ignition coils, can further enhance performance in high-performance engines.

Considerations Regarding Ignition Coils

Despite their critical role in engine performance, ignition coils have some considerations to account for. For example.the production of ignition coils can be environmentally damaging due to the use of rare earth metals and other materials. Additionally, the disposal of e-waste can lead to environmental pollution if not handled correctly.

Benefits of Ignition Coils

The primary benefit of ignition coils is that they provide a reliable and consistent spark that is essential for the proper functioning of internal combustion engines. This reliable spark leads to improved fuel efficiency, reduced emissions, and better overall performance. Additionally, ignition coils are relatively simple and compact components that can be easily integrated into various engine designs, making them a versatile solution for a wide range of applications.

Another benefit of ignition coils is that they are generally quite durable and long-lasting. Most modern ignition coils are made using high-quality materials and advanced manufacturing techniques, which means that they can withstand the extreme heat and vibration associated with engine operation. This durability means that ignition coils are often maintenance-free and can provide years of reliable service.

Ignition coils also play an essential role in engine safety. By providing a reliable spark, ignition coils ensure that the fuel-air mixture is properly ignited, which reduces the risk of engine misfires and subsequent engine damage. Furthermore, ignition coils help to prevent engine overheating and other issues that can lead to potentially dangerous situations. In addition to these benefits, ignition coils can also provide improved engine response and smoother acceleration by delivering a more powerful spark.

Applications of Ignition Coils

Ignition coils can be used in various applications. In rocket engines, for example, ignition coils are used to create a spark that ignites the fuel, which in turn generates the thrust needed for the rocket to launch. In medical equipment, meanwhile, ignition coils are used to produce the high-voltage pulses needed for creating the magnetic field in an MRI machine. Additionally, ignition coils are used in portable generators to provide the spark necessary to ignite the fuel and generate electricity. They are also used in welding equipment, where the high-voltage pulse produced by the ignition coil is used to create an arc that melts the metal being welded. Furthermore, ignition coils are essential in high-performance vehicles and racing engines for achieving maximum power output and quick spark delivery. Ignition coils that are designed for use in high-performance vehicles often have more robust construction and more powerful windings to deliver a stronger spark. Finally, double ignition coils are also commonly used in racing engines to provide an extra spark, which can help improve performance.

The Future of Ignition Coils

In the future, advancements in materials and designs are expected to improve the efficiency of ignition coils. For example, new materials like graphene may provide higher conductivity and thermal efficiency, making them ideal for use in high-performance engines. Additionally, advancements in electronic control systems may enable more precise control over ignition timing, further improving engine performance and reducing emissions.

Another area of potential future development for ignition coils is in the field of electric vehicles. As the demand for electric vehicles continues to grow, the need for high-efficiency ignition systems will become increasingly important. Electric vehicles rely on batteries to power their motors, which means that ignition coils will need to be designed to work with high-voltage electrical systems. Furthermore, ignition coils will need to be optimized for use with different types of batteries, such as lithium-ion or solid-state batteries.

In addition to improvements in performance, the future of ignition coils may also involve changes in how they are produced and disposed of. Manufacturers may move towards using more sustainable and environmentally friendly materials in the production of ignition coils. Additionally, the development of more efficient recycling processes may help reduce the amount of e-waste generated by ignition coils and other automotive components.

Choosing the Right Ignition Coil Supplier

To ensure you have the most positive outcome when purchasing ignition coils from an ignition coil supplier, it is important to compare several companies using our directory of ignition coil suppliers. Each ignition coil supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each ignition coil business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple ignition coil companies with the same form.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services