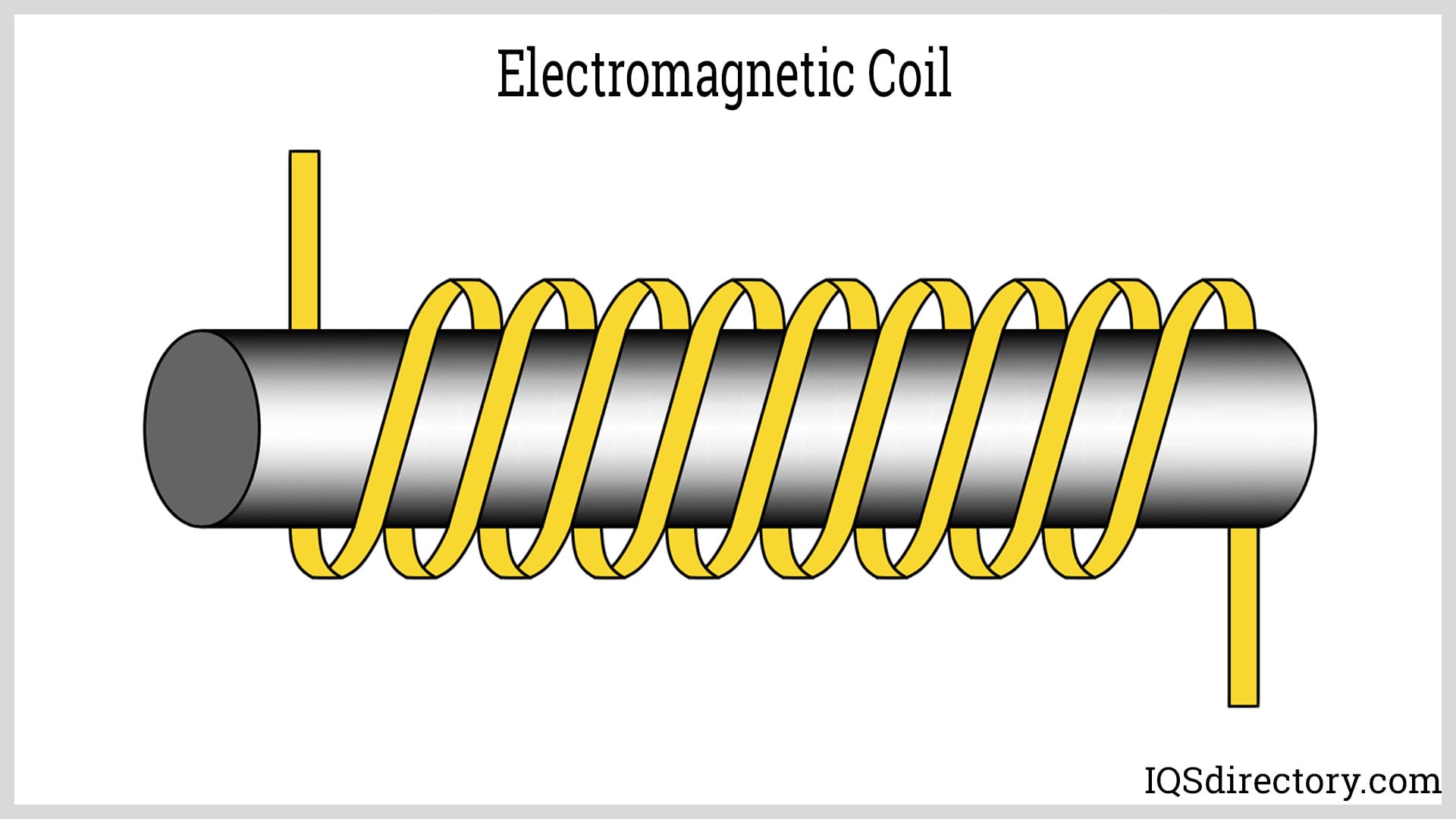

Electromagnetic coils are electrical conductors wound around a core that produce a magnetic field when an electric current passes through them. Electromagnetic coils are an essential component in various electrical and electronic devices, from generators and motors to speakers and microphones. Read More…

We are proud of the craftsmanship of our engineers. All of our products are made right here in the United States and we promise that these items are created from high quality resources. Our electrical coils are unique and efficient.

Established in 1973, Classic Coil Company is a Contract Manufacturer of electronic coils. We manufacture coils for a variety of industries; winding wire gauges from 4-58 AWG. We are ISO 9001-2015 certified, ITAR registered and DFARS Compliant. Our Engineering services allow us to assist with design, reduce cost, and increase efficiency in production. Call or visit our website to learn more about...

Since 1962, Torelco has been a supplier of electric coils and transformers of superior quality. We offer custom coils, solenoid coils, ferrite core coils & toroid wound coils to serve a range of industries. Markets served include medical, military, electronics, and industrial. When you work with us, our promise is to build to the exact specifications and meet the custom needs of our customers.

Check out what’s new online at Precision Econowind, manufacturer of the highest quality custom coils at reasonable prices, with on time delivery. Serving the coil industry for over 30 years, we’re experienced with producing loudspeaker & medical industry coils, coils wound on customers’ bobbins/tooling; freestanding, flat wire, edge wound, square, rectangle & shaped coils. Submit your specs ...

Triad Magnetics has been in the electric coils industry for over 75 years. Giving us the knowledge and expertise to be one of the best in the industry. We have a wide range of electric coils and inductors as well as the ability to custom engineer and manufacture electric coils to our customer’s needs. Having served the needs of many industries for more than half a century, Triad believes its...

More Electromagnetic Coil Manufacturers

Components of an Electromagnetic Coil

An electromagnetic coil consists of a wire wrapped around a core and insulated to prevent short circuits. When an electric current passes through the wire, a magnetic field is generated, which can be used for a range of purposes. The core material, wire gauge, number of turns, and shape of the coil all affect its magnetic field strength, inductance, and other properties.

Variations of Electromagnetic Coils

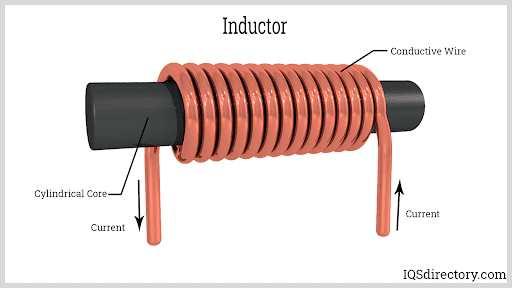

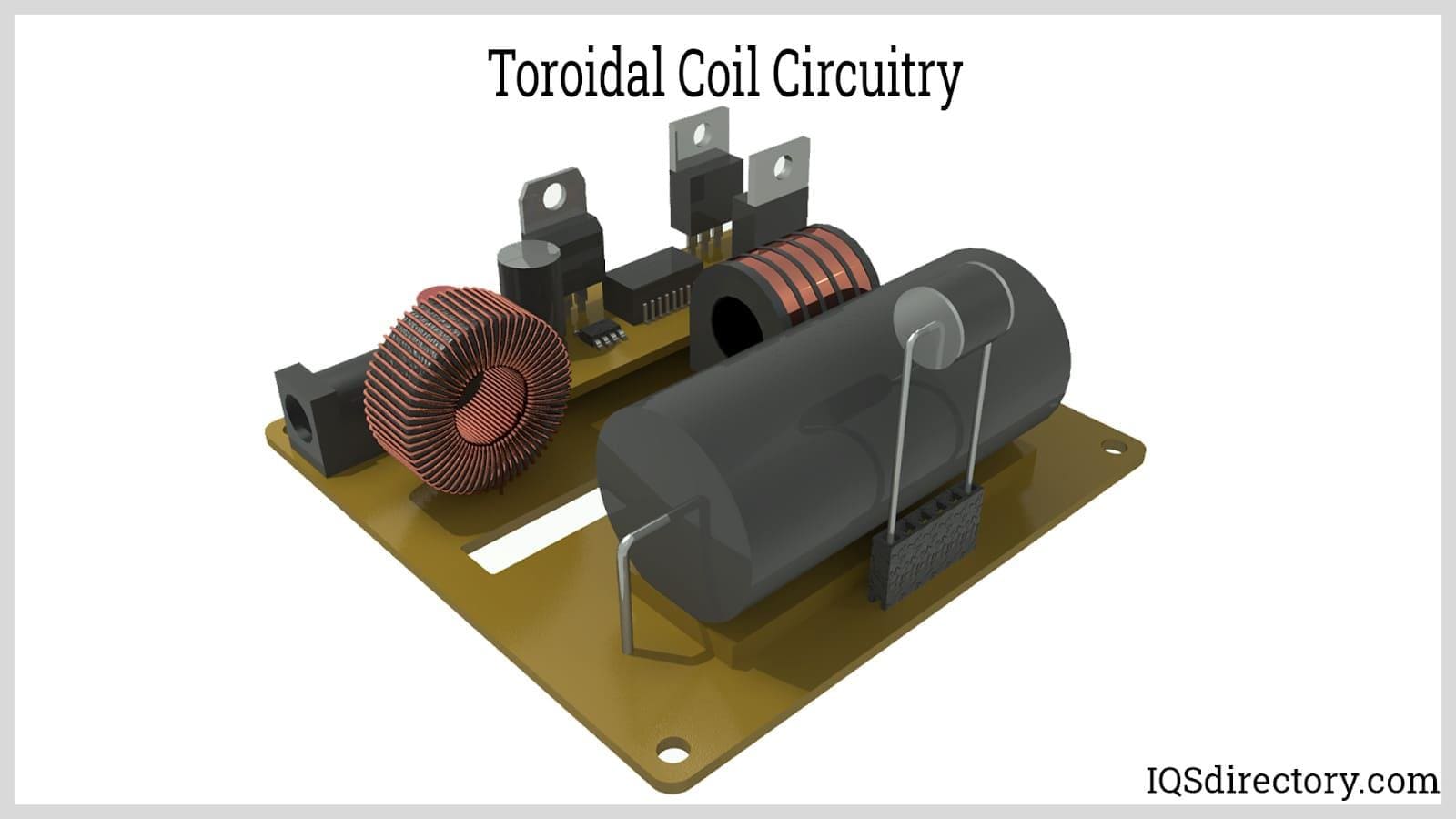

There are several variations of electromagnetic coils, each with their own unique features and applications. Copper is a common choice for wire due to its high conductivity, while aluminum coils are lightweight and cost-effective. Superconducting materials, such as niobium-titanium, can produce extremely strong magnetic fields with minimal power loss. The core material can also vary, with air-core coils having a hollow center and no magnetic material, making them ideal for applications that require precise tuning or low inductance. Iron-core coils are wrapped around a ferromagnetic material, which intensifies the magnetic field, making them suitable for transformers and inductors. Toroidal coils, with a donut-shaped core, offer efficient magnetic coupling and are used in a wide range of applications. Additionally, the design of the coil can also vary itself, with solenoid coils consisting of a long cylindrical wire wrapped in a helix around a core, producing a strong and uniform magnetic field, while helical coils are shaped like a spiral and are suitable for applications that require variable inductance.

Considerations Regarding Electromagnetic Coils

Despite the numerous benefits of electromagnetic coils, there are also some considerations to keep in mind. The production and disposal of the materials used in the coils can have an undesirable impact on the environment, and safety concerns can arise due to the strong magnetic fields produced. Electromagnetic interference can also be an issue in certain applications.

Benefits of Electromagnetic Coils

Electromagnetic coils offer several benefits that make them an essential component in various electrical and electronic devices. One of the most significant advantages of electromagnetic coils is their efficiency. By generating a magnetic field through an electrical current, electromagnetic coils can convert electrical energy into magnetic energy and vice versa with minimal energy loss. This efficiency makes them ideal for applications where energy conservation is critical, such as electric motors and generators. Another advantage of electromagnetic coils is their versatility. With variations in materials, size, and shape, electromagnetic coils can be customized to fit the specific needs of different applications. This ability to fine-tune the coil's properties, such as inductance and magnetic field strength, allows for precise control and performance in various systems. The precision offered by electromagnetic coils is another additional benefit. The magnetic field produced by the coil can be manipulated and controlled to exact specifications, which is crucial for applications that require precise tuning, such as inductors and transformers used in power supplies and audio equipment. The precision offered by electromagnetic coils also makes them suitable for use in medical imaging, such as magnetic resonance imaging (MRI), where precise control of the magnetic field is essential.

Applications of Electromagnetic Coils

Electromagnetic coils have a vast range of applications due to their ability to convert electrical energy into magnetic energy and vice versa. One significant application of electromagnetic coils is in electric motors and generators, where they produce the magnetic field that rotates the motor and generates electricity. Electromagnetic coils are also found in speakers and microphones, where they convert electrical signals into sound waves and vice versa. Another common application of electromagnetic coils is in transformers and inductors used in power supplies. In transformers, electromagnetic coils are used to step up or step down the voltage of an alternating current (AC) power supply, making them essential for power distribution and transmission. Inductors, on the other hand, are used to store energy in a magnetic field and are critical for filtering out unwanted signals and noise in power supplies. In addition to their use in power supplies, electromagnetic coils are also used in medical imaging equipment, such as magnetic resonance imaging (MRI) machines. MRI machines use powerful electromagnetic coils to create a strong magnetic field that aligns the protons in the body's tissues. Radio waves are then used to disrupt the alignment of the protons, and when the protons realign, they emit a signal that can be detected and translated into images.

Choosing the Correct Electromagnetic Coil Supplier

To ensure you have the most beneficial outcome when purchasing electromagnetic coils from an electromagnetic coil supplier, it is important to compare several companies using our directory of electromagnetic coil suppliers. Each electromagnetic coil supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each electromagnetic coil business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple electromagnetic coil companies with the same form.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services