A custom coil refers to an electrical conductor made with the general purpose of converting electrical energy into linear motion but customized with specific materials required for a specific application. Read More…

We are proud of the craftsmanship of our engineers. All of our products are made right here in the United States and we promise that these items are created from high quality resources. Our electrical coils are unique and efficient.

Established in 1973, Classic Coil Company is a Contract Manufacturer of electronic coils. We manufacture coils for a variety of industries; winding wire gauges from 4-58 AWG. We are ISO 9001-2015 certified, ITAR registered and DFARS Compliant. Our Engineering services allow us to assist with design, reduce cost, and increase efficiency in production. Call or visit our website to learn more about...

Since 1962, Torelco has been a supplier of electric coils and transformers of superior quality. We offer custom coils, solenoid coils, ferrite core coils & toroid wound coils to serve a range of industries. Markets served include medical, military, electronics, and industrial. When you work with us, our promise is to build to the exact specifications and meet the custom needs of our customers.

Check out what’s new online at Precision Econowind, manufacturer of the highest quality custom coils at reasonable prices, with on time delivery. Serving the coil industry for over 30 years, we’re experienced with producing loudspeaker & medical industry coils, coils wound on customers’ bobbins/tooling; freestanding, flat wire, edge wound, square, rectangle & shaped coils. Submit your specs ...

Triad Magnetics has been in the electric coils industry for over 75 years. Giving us the knowledge and expertise to be one of the best in the industry. We have a wide range of electric coils and inductors as well as the ability to custom engineer and manufacture electric coils to our customer’s needs. Having served the needs of many industries for more than half a century, Triad believes its...

More Custom Coil Manufacturers

What Is a Custom Coil?

A custom coil is a precisely engineered electromagnetic component designed to meet specialized requirements in a wide range of industrial, commercial, and medical applications. Unlike standard off-the-shelf coils, custom coils are tailored according to exact specifications regarding form material, wire material, wire gauge/type, winding geometry, and insulation class. The process of custom coil design involves working closely with the end user or original equipment manufacturer (OEM) to define parameters such as inductance, resistance, current capability, voltage rating, frequency response, and environmental durability.

The types of wire commonly used in custom coil manufacturing include copper—renowned for its high conductivity and efficiency—and aluminum, valued for its lightweight properties and cost-effectiveness. Specialty applications may require wires made from platinum, gold, silver, stainless steel, titanium, or advanced titanium alloys for enhanced biocompatibility, corrosion resistance, or unique magnetic properties.

During the wire production and winding process, various techniques are used, such as single layer, multi-layer, random layer, self-bonding, dry or epoxy wound, precision winding, and either manual or automated winding. Each technique impacts the coil’s performance, reliability, and suitability for its intended application. For example, precision winding is often crucial for high-frequency coils used in RF (radio frequency) and microwave technologies, while epoxy wound coils provide enhanced mechanical stability and moisture resistance.

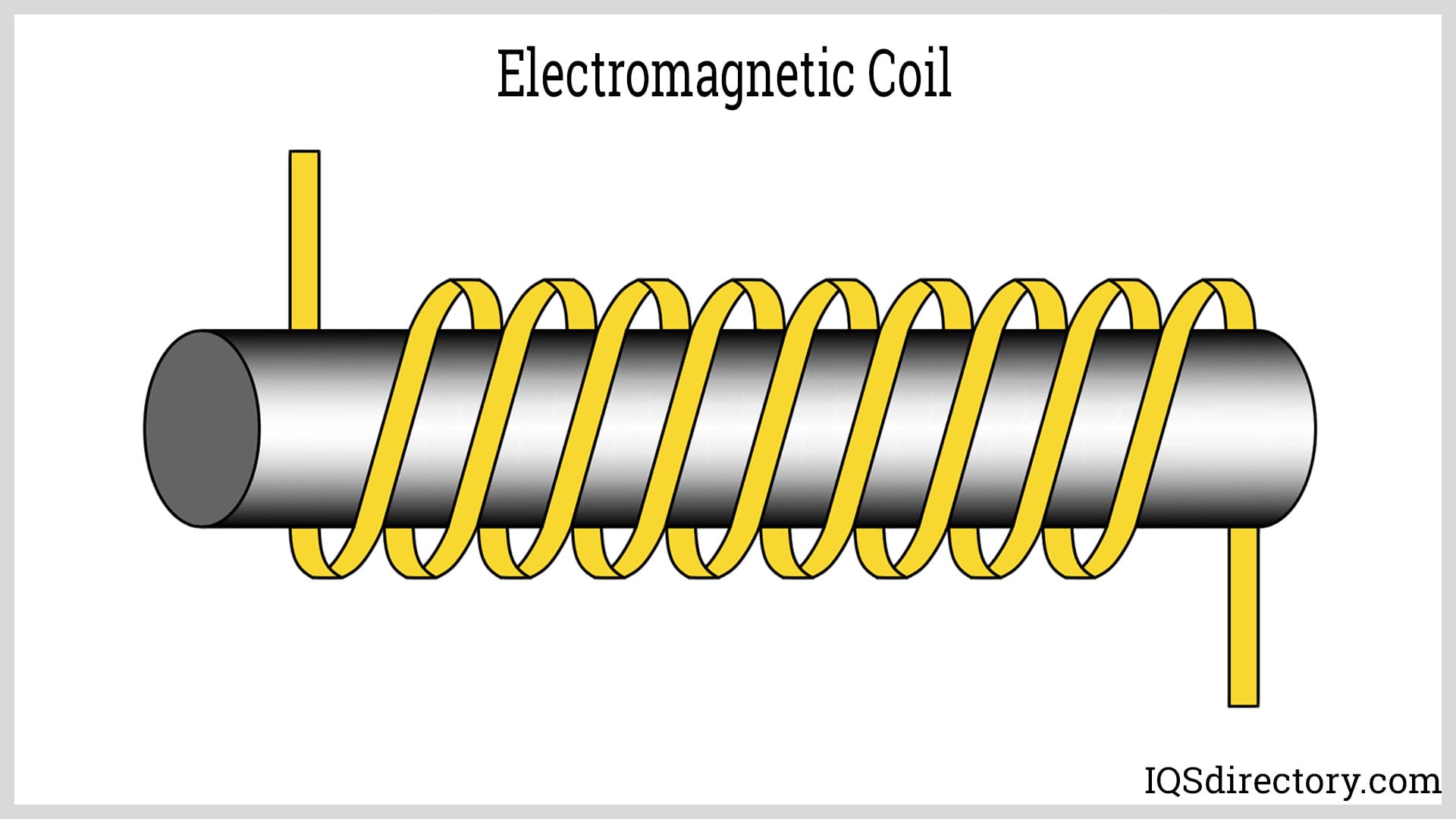

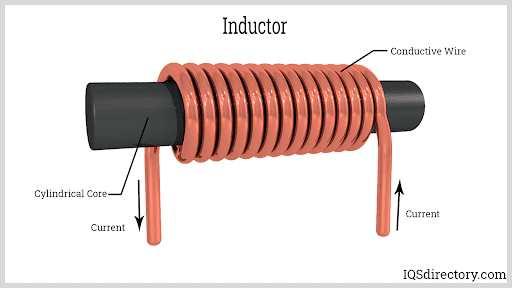

Custom coils serve as the heart of many electromagnetic devices. The primary types of coils, classified by their function, include electromagnets, transformers, transducer coils, and inductors. Inductors, often referred to as reactors, generate a magnetic field that interacts with the coil itself, inducing a back electromagnetic force (EMF). Electromagnets, on the other hand, are used to generate a magnetic field for external applications, frequently providing mechanical force, motion control, or actuation in electromechanical systems.

How Custom Coils Are Made

The process of custom coil winding is a highly specialized manufacturing operation. It begins with twisting ultra-fine wires around a contained core or pin, creating a round, helical, or even spherical shape depending on the application requirements. State-of-the-art coil winding machines are often employed for applications demanding high precision, repeatability, and scalability, while manual winding is still used for prototype or low-volume custom coil projects.

Different users may have distinct requirements for coil shape and size, such as coreless coils for minimally invasive medical implants or applications where a magnetic core would cause interference. To manufacture coreless coils, the core is removed after winding, enabling the insertion of the coil into narrow spaces like blood vessels or microfluidic channels.

Coreless custom coils offer significant advantages, especially for sensitive electronic and biomedical uses. Manufacturers can produce coils with varying thicknesses, diameters, and inductances by altering the number of windings and wire gauge. Winding configurations fall into categories such as single-layer or multi-layer winding, each affecting inductance, resistance, and magnetic field strength.

Most ultra-fine wires are made from copper due to its superior conductivity, but alternative materials like stainless steel, gold, platinum, titanium, aluminum, and titanium alloys are selected for unique application requirements, such as biocompatibility for implantable devices or high-temperature resistance for aerospace coils.

One of the biggest challenges in custom coil manufacturing is handling ultra-fine wires—connecting, bonding, and insulating them without damage. Advanced techniques like thermal pressure bonding and laser welding are increasingly used to ensure reliable electrical contact and mechanical strength, even in miniature and micro-coil designs.

Want to learn more about the coil winding process? Explore our detailed guide on coil winding techniques and best practices to understand how expert manufacturers meet diverse custom coil needs.

Types of Custom Coils

Custom coils can be categorized based on several factors, including wire type, application area, winding process, coil geometry, and the materials used for both form and wire. Understanding these categories is crucial for engineers, buyers, and designers who need to source the right coil solution for their application.

Frequency-Based Custom Coils

Frequency-based custom coils are designed to operate within specific electrical frequency ranges. For example, direct current (DC) coils are optimized for steady, unidirectional current in their windings, which is common in solenoid actuators and DC relays.

Audio frequency coils (operating below 20 kHz) are used in audio transformers, crossover inductors, and telecommunications devices. Meanwhile, radio frequency (RF) coils and microwave coils are engineered for operation at much higher frequencies, from 20 kHz up to several gigahertz, making them essential in wireless communication, MRI equipment, and radar systems.

Function-Based Custom Coils

Function-based custom coils are classified by their specific roles within electrical and electronic systems. Key examples include:

- Electromagnets: Create strong, controllable magnetic fields for applications in motors, actuators, lifting magnets, and magnetic separation equipment.

- Inductors: Store energy in a magnetic field, filter electrical signals, suppress electromagnetic interference (EMI), and regulate power in power supplies and converters.

- Transformers: Transfer electrical energy between circuits, step voltage up or down, and provide isolation in power distribution or signal conditioning.

- Transducer Coils: Convert electrical signals into mechanical or acoustic energy (and vice versa), crucial in sensors, microphones, speakers, and ultrasonic transducers.

Electromagnets are engineered to generate intense, targeted magnetic fields for external force or motion, whereas inductors are mainly used to influence current flow, filter signals, and store energy in magnetic fields.

Shape and Construction-Based Custom Coils

Another important classification is by physical shape and construction method. Common coil shapes include:

- Solenoid Coils: Cylindrical, often used in actuators and valves.

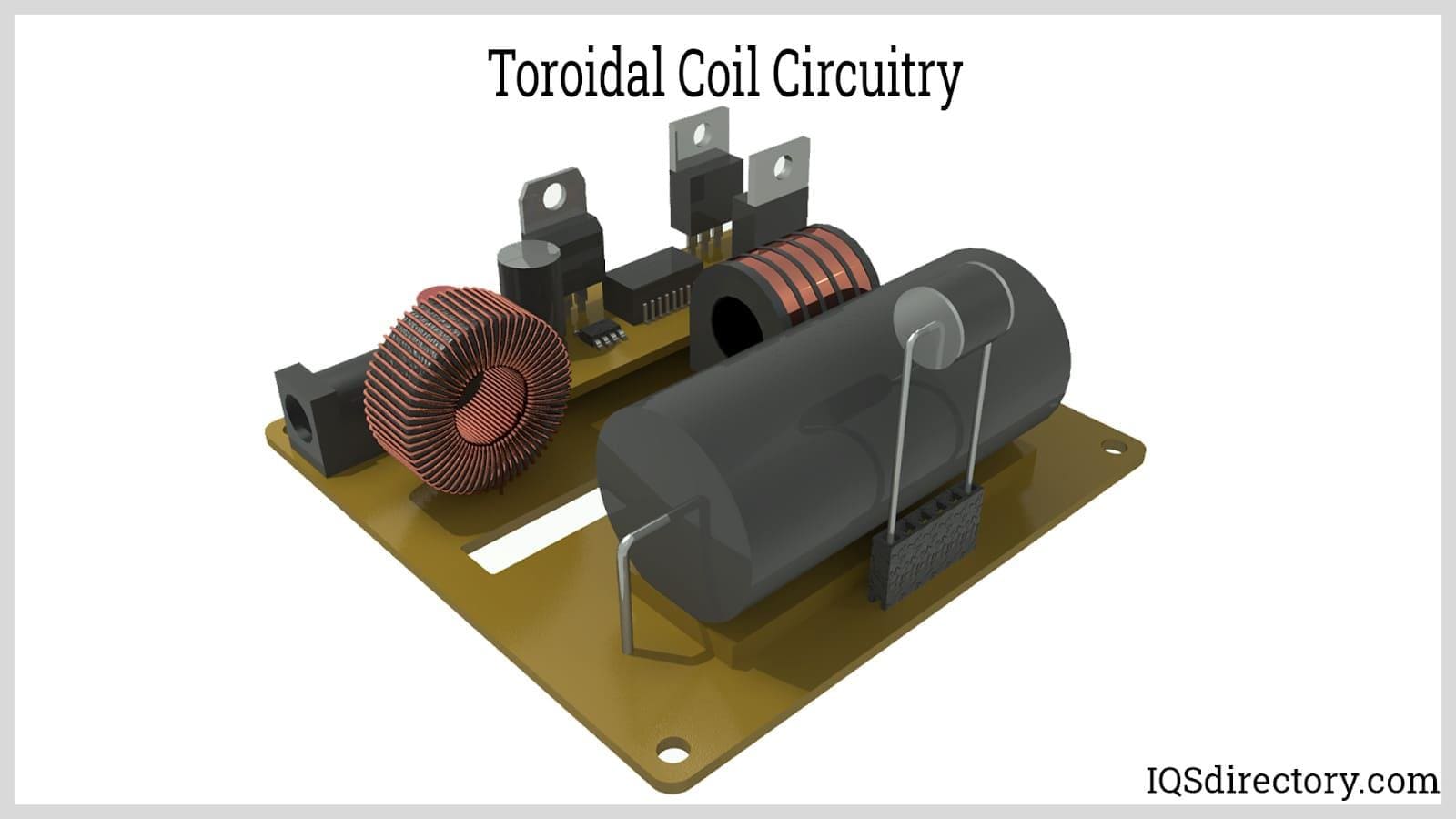

- Toroidal Coils: Donut-shaped, offering minimal electromagnetic interference (EMI) and used in power supplies, transformers, and audio equipment.

- Planar Coils: Flat, spiral-shaped, suitable for printed circuit boards (PCBs) and wireless charging applications.

- Bobbin-Wound Coils: Wound around a spool or bobbin for ease of assembly and integration.

- Air-Core and Iron-Core Coils: With or without magnetic cores, each offering unique properties for different frequency and power handling requirements.

Which coil geometry is best for your application? Contact our coil engineering team for guidance on selecting the optimal shape, core material, and winding technique.

Applications and Uses of Custom Coils

Custom coils play an indispensable role in modern technology, powering and controlling a vast array of devices across numerous industries. Their versatility and adaptability make them ideal for mission-critical applications where standard coils would not suffice. Here are some of the most significant uses for custom-wound electromagnetic coils:

Medical Devices

In the medical field, custom coils are vital components in devices such as pain management devices, pacemaker monitors, and miniature implantable sensors. For electrical ablation therapies, microwave and radio frequency coils are preferred due to their precise energy delivery and minimal invasiveness.

Electromagnetic custom coils are also utilized in dental equipment, electrophysiology, and orthopedic treatments, offering high reliability and biocompatibility for demanding medical environments.

Industrial and Commercial Applications

In the industrial sector, custom coils are essential for measurement instrumentation, process control systems, electromechanical actuators, and automation equipment. These coils can be found in everything from power transformers, relay coils, solenoids, automotive ignition systems, to robotics and factory automation machinery.

Custom coils are also the backbone of orientation and navigation sensors, used in aerospace and automotive guidance systems, and in power electronics for filtering, voltage conversion, and EMI suppression.

Consumer Electronics and Wireless Technology

In the world of consumer electronics, custom coils enable wireless charging, RFID tags, audio devices, speakers, microphones, and smart home systems. Planar and micro-coils are increasingly used in high-density circuit boards and wearable technology.

Scientific Research & Laboratory Equipment

Laboratories and research facilities rely on custom coils for precision magnetic field generation, NMR (nuclear magnetic resonance) spectroscopy, mass spectrometry, particle accelerators, and measurement instrumentation. Custom-wound coils offer the accuracy and repeatability needed for cutting-edge scientific discovery.

Automotive and Aerospace

In automotive systems, custom coils are integral to ignition systems, transmission solenoids, fuel injectors, ABS modules, and advanced driver-assistance systems (ADAS). The aerospace industry utilizes high-performance coils for navigation, actuators, power conversion, and avionics, where reliability under extreme conditions is paramount.

Questions to Ask When Specifying Custom Coils

- What are the required electrical properties: inductance, resistance, and current/voltage ratings?

- Which core material (air, iron, ferrite, etc.) is optimal for your frequency and power requirements?

- What environmental conditions (temperature, humidity, vibration) will the coil face?

- Is biocompatibility or corrosion resistance necessary for your application?

- Will the coil be embedded, exposed, or require specialized encapsulation?

- What are your size, weight, and mounting constraints?

Need help specifying a custom coil? Connect with our engineering experts for personalized assistance and rapid prototyping options.

Choosing the Right Custom Coil Manufacturer

Selecting the best custom coil manufacturer is a critical decision that directly affects the performance, lead time, and reliability of your final product. Here are key considerations when evaluating custom coil suppliers:

- Technical Capabilities: Does the manufacturer offer advanced coil winding techniques, in-house prototyping, and full-scale production?

- Material Selection: Can they source and process specialty wire and core materials for your unique requirements?

- Quality Assurance: Are ISO certifications, traceability, and rigorous testing protocols in place?

- Design Support: Will they assist with engineering, simulation, and optimization of your coil design?

- Lead Time and Scalability: Can they meet your delivery schedule for both prototypes and volume runs?

- Regulatory Compliance: Are coils built to meet industry standards (UL, RoHS, REACH, FDA, IEC, etc.)?

For the most positive outcome when purchasing custom coils, it is important to compare several manufacturers using our comprehensive directory of custom coil companies. Each custom coil manufacturer has a business profile page highlighting their areas of expertise, manufacturing capabilities, and certifications, along with a contact form to directly communicate for more information or to request a quote. Review each custom coil business using our proprietary website previewer for a better understanding of what each company specializes in. Then, use our simple RFQ form to contact multiple businesses with the same form and receive competitive proposals for your project.

Ready to request a quote for your custom coil project? Submit your requirements now and get responses from top-rated custom coil manufacturers.

Still have questions? Browse our custom coil FAQ or reach out to our team for expert advice on design, prototyping, and production.

Benefits of Custom Coils

- Optimized Performance: Tailored electrical and mechanical properties meet exact system requirements, improving efficiency and functionality.

- Space and Weight Savings: Custom geometry allows integration into compact or irregular enclosures where standard coils cannot fit.

- Enhanced Reliability: Selection of premium materials and advanced insulation techniques yields longer service life and reduced maintenance.

- Faster Time-to-Market: Collaborative design and rapid prototyping accelerate development cycles for new products.

- Compliance and Traceability: Manufacturers can ensure custom coils adhere to strict regulatory, safety, and quality standards.

- Competitive Advantage: Unique coil solutions can provide superior performance or enable features that differentiate your product in the marketplace.

Is a custom coil the right solution for your project? Schedule a consultation to discuss your engineering and application challenges.

Frequently Asked Questions About Custom Coils

What is the typical lead time for custom coil manufacturing?

Lead times can range from a few days for rapid prototyping to several weeks for complex, high-volume orders. Factors influencing lead time include material availability, coil complexity, testing requirements, and current production schedules.

How do I ensure my custom coil meets industry standards?

Partner with a manufacturer who is certified to relevant quality and safety standards (such as ISO, UL, or FDA for medical coils) and who provides full documentation, traceability, and compliance reports.

Can custom coils be made for harsh environments?

Yes. Custom coils can be designed with robust encapsulation, specialized insulation, and corrosion-resistant materials to withstand extreme temperatures, humidity, vibration, and chemical exposure.

What information do I need to request a custom coil quote?

Essential details include electrical specifications (inductance, resistance, voltage, current), dimensional drawings or models, environmental conditions, core/wire materials, and any relevant certifications or standards.

Where can I find technical resources for coil design?

Explore our technical resources for in-depth guides, engineering calculators, and industry articles about custom coil technology, design, and manufacturing.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services