A choke coil is an inductive coil that blocks alternating currents of a higher frequency while passing direct and alternating currents of lower frequencies in an electrical circuit. Read More…

We are proud of the craftsmanship of our engineers. All of our products are made right here in the United States and we promise that these items are created from high quality resources. Our electrical coils are unique and efficient.

Established in 1973, Classic Coil Company is a Contract Manufacturer of electronic coils. We manufacture coils for a variety of industries; winding wire gauges from 4-58 AWG. We are ISO 9001-2015 certified, ITAR registered and DFARS Compliant. Our Engineering services allow us to assist with design, reduce cost, and increase efficiency in production. Call or visit our website to learn more about...

Since 1962, Torelco has been a supplier of electric coils and transformers of superior quality. We offer custom coils, solenoid coils, ferrite core coils & toroid wound coils to serve a range of industries. Markets served include medical, military, electronics, and industrial. When you work with us, our promise is to build to the exact specifications and meet the custom needs of our customers.

Check out what’s new online at Precision Econowind, manufacturer of the highest quality custom coils at reasonable prices, with on time delivery. Serving the coil industry for over 30 years, we’re experienced with producing loudspeaker & medical industry coils, coils wound on customers’ bobbins/tooling; freestanding, flat wire, edge wound, square, rectangle & shaped coils. Submit your specs ...

Triad Magnetics has been in the electric coils industry for over 75 years. Giving us the knowledge and expertise to be one of the best in the industry. We have a wide range of electric coils and inductors as well as the ability to custom engineer and manufacture electric coils to our customer’s needs. Having served the needs of many industries for more than half a century, Triad believes its...

More Choke Coil Manufacturers

What Is a Choke Coil?

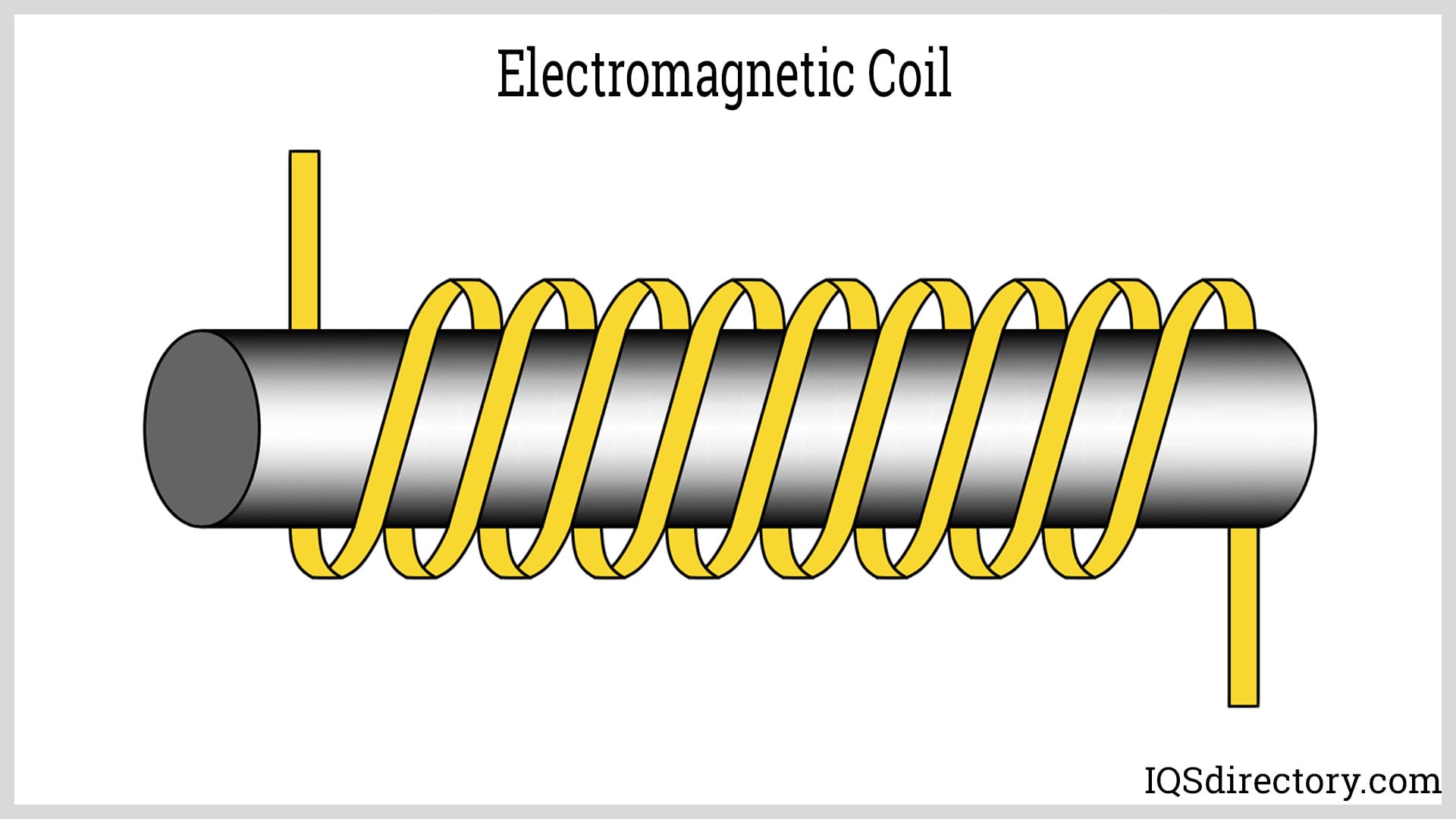

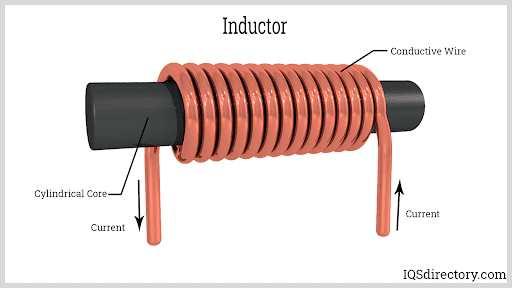

A choke coil is an essential component in electrical and electronic circuits, primarily designed to block or "choke" high-frequency alternating current (AC) while allowing low-frequency or direct current (DC) to pass through. Structurally, a choke coil typically consists of a coil of insulated wire wound around a magnetic core, such as iron, ferrite, or air. Some chokes, particularly those used at high frequencies, utilize a bead or donut-shaped ferrite material threaded onto a wire. This design variation is based on frequency filtering requirements and the desired inductance value.

The impedance of a choke coil increases with frequency, making it highly effective for filtering unwanted noise or interference in power supplies, audio equipment, data transmission lines, and radio frequency (RF) circuits. Due to its low electrical resistance, it allows DC and low-frequency AC to flow with minimal power loss, but its inductive reactance significantly limits higher-frequency alternating currents.

How Choke Coils Function

The primary function of a choke coil is to act as a frequency-dependent filter, enabling desired signals to pass while attenuating or blocking unwanted frequencies. This function is critical in power electronics, signal processing, and electromagnetic interference (EMI) suppression. By leveraging the property of inductance, a choke coil resists sudden changes in current, which is particularly useful in smoothing out voltage fluctuations and eliminating noise in sensitive circuits.

When an alternating current flows through the coil, it generates a magnetic field that opposes the change in current (known as Lenz's Law). This opposition increases with frequency, effectively filtering out AC components above a certain threshold. DC currents, on the other hand, are unaffected and continue to flow through the coil. The choice of core material—such as air, ferrite, or iron—directly influences the inductance value and the frequency response of the choke coil. For high-frequency filtering, air or ferrite cores are preferred, while iron cores are common in low-frequency applications.

In essence, a choke coil stores energy in its magnetic field when current passes through, releasing it gradually to maintain a steady flow of electricity. This property is crucial in power supply regulation, signal integrity enhancement, and EMI/RFI suppression.

Types of Choke Coils

Choke coils are classified based on their application areas, inductance ratings, voltage ratings, and construction designs. Understanding the different types of choke coils and their unique characteristics is essential for selecting the right component for your project or application.

Audio Frequency Choke Coil

Audio frequency choke coils (AFCs) are designed to operate at low frequencies, typically in the audio range (20 Hz to 20 kHz). They commonly feature ferromagnetic cores, such as laminated iron, to enhance their inductance. The construction is similar to transformers, often incorporating an air gap to prevent core saturation and improve linearity. The iron core increases inductance for a given coil size, making AFCs suitable for filtering and smoothing operations in audio equipment and power supplies.

Historically, AFCs were extensively used in rectifier power supplies for vacuum tube equipment, such as radio receivers and audio amplifiers. In modern applications, audio frequency chokes continue to play a vital role in subwoofers, crossover networks, and noise filtering in analog circuits. They are often paired with large electrolytic capacitors to reduce voltage ripple and stabilize DC output in power supply circuits. Removing a choke from such a filter can lead to excessive voltage and increased stress on rectifiers and capacitors.

- Key Benefits: Effective smoothing of DC voltage, reduction of audio noise, and enhanced sound quality in audio systems.

- Common Applications: Audio amplifiers, subwoofers, crossover networks, vintage radio equipment, and regulated power supplies.

Radio Frequency Choke Coil

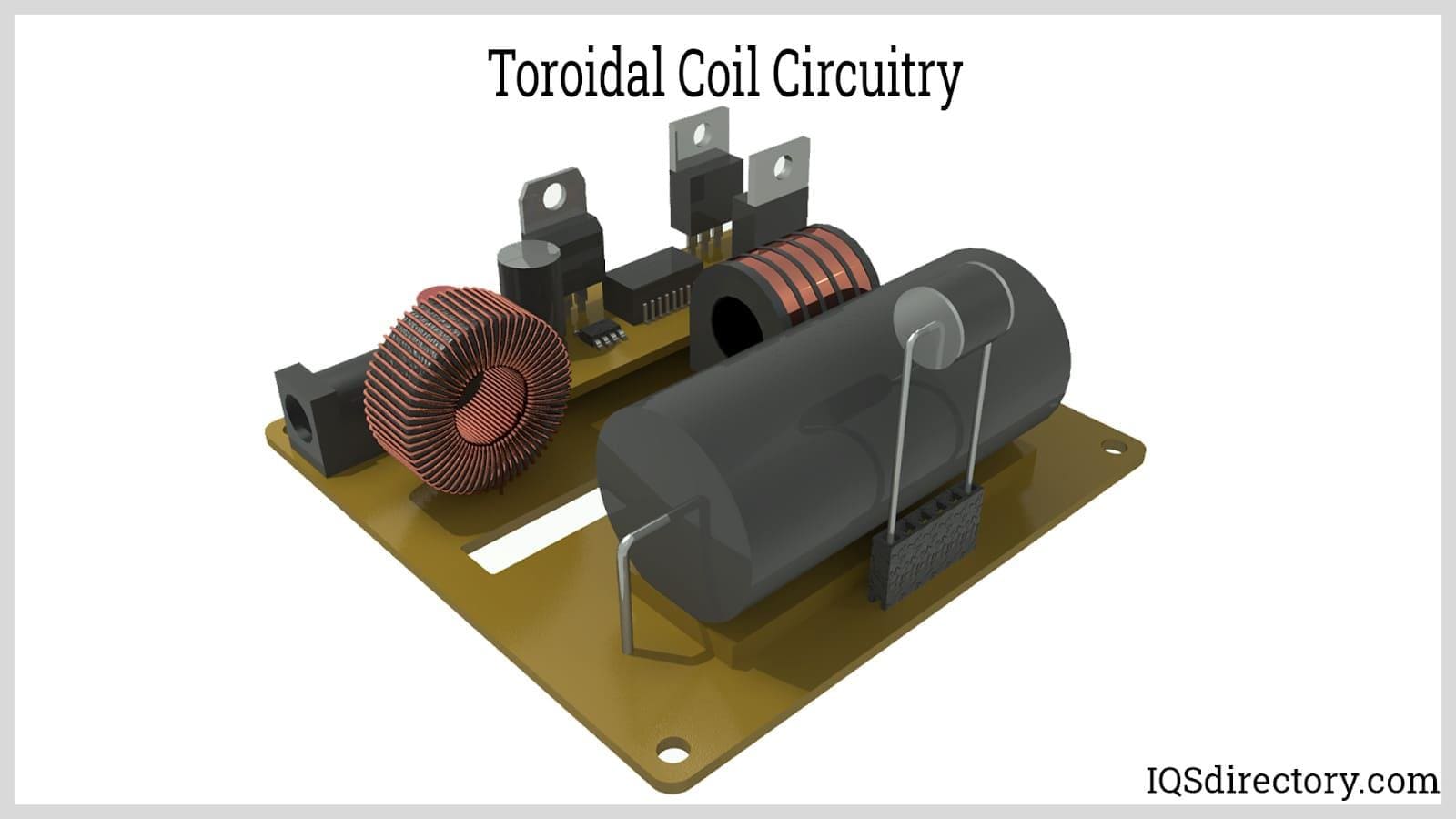

Radio frequency choke coils (RFCs) are engineered for high-frequency operation, typically in the kilohertz (kHz) to gigahertz (GHz) range. These chokes often use ferrite or powdered iron cores to increase inductance and minimize core losses at high frequencies. The coils are wound in special patterns, such as basket-weave or honeycomb, to reduce parasitic capacitance and mitigate proximity effects, ensuring efficient performance at radio and microwave frequencies.

RFCs are crucial in blocking high-frequency signals in power supply lines, preventing RF interference from contaminating sensitive circuits. They are widely used in communication devices, signal processing equipment, and computer peripherals. For extremely high-frequency applications, non-magnetic cores or ferrite beads are preferred to achieve low inductance and effective noise suppression. Ferrite beads, commonly seen on USB, HDMI, and other data cables, serve as modern RF chokes to eliminate digital RF noise and enhance signal integrity.

- Key Benefits: Suppression of RF interference, improved signal clarity, and protection of sensitive electronic equipment.

- Common Applications: Communication systems, RF transmitters and receivers, data cables, EMI filtering, and high-frequency switch-mode power supplies.

Common Mode Choke Coil

Common mode choke coils (CMCs) are designed to suppress common mode noise and electromagnetic interference in power and signal lines. Unlike conventional chokes, CMCs consist of two or more windings on a single core, typically made of ferrite. The unique winding configuration allows common mode currents—those flowing in the same direction in both wires—to be blocked, while differential mode currents (the intended signals) pass with minimal impedance.

This selective blocking is achieved because differential mode currents generate opposing magnetic fields that cancel each other out, resulting in low net inductance. In contrast, common mode currents generate reinforcing magnetic fields, creating high inductance and effectively attenuating EMI. CMCs are indispensable in power electronics, power supplies, motor drives, and data transmission systems to comply with EMC regulations and prevent equipment malfunction due to noise.

- Key Benefits: High suppression of common mode noise, compliance with electromagnetic compatibility (EMC) standards, and enhanced reliability of electronic systems.

- Common Applications: Power supply input lines, USB and Ethernet cables, motor drives, industrial automation, and EMI/RFI filtering.

Applications and Uses of Choke Coils

Choke coils play a pivotal role in a wide array of industrial, commercial, and consumer electronics applications. Their ability to filter unwanted frequencies, prevent electromagnetic interference, and stabilize voltage makes them indispensable in modern electronic design. Here are some of the most common uses:

- Power Supply Filtering: Choke coils are integral to high voltage coil systems, acting as smoothing filters in AC-DC converters, inverter circuits, and voltage regulators. They help minimize voltage ripple and protect downstream components from transients.

- Lighting Systems: In fluorescent tube lights, choke coils are used to generate the initial high voltage required for ignition and to limit current during steady operation, extending lamp life and improving efficiency.

- Data Transmission and Communication: Choke coils are employed in USB, HDMI, Ethernet, and other data cables to suppress high-frequency noise, ensuring reliable data transfer and compliance with EMC standards.

- Audio and Signal Processing: Audio frequency chokes are used in subwoofers, loudspeakers, and crossover networks to filter out unwanted frequencies, resulting in clearer sound and reduced distortion.

- Electromagnetic Interference (EMI) Suppression: Choke coils, especially common mode chokes and ferrite beads, are essential for reducing EMI in power supplies, switching regulators, and sensitive analog/digital circuits.

- Motor Control: In DC and AC motor controllers, choke coils help produce smooth DC currents, reduce electrical noise, and protect against voltage spikes.

- Renewable Energy Systems: Choke coils are used in solar inverters and wind turbine controllers to stabilize output, filter harmonics, and improve energy conversion efficiency.

- Automotive Electronics: Choke coils mitigate EMI in automotive power systems, infotainment modules, and advanced driver-assistance systems (ADAS), ensuring reliable vehicle operation.

Want to Learn More About Choke Coil Applications?

Wondering how choke coils can improve your specific system? Explore our resource center to learn more about selecting the right choke coil for applications like: power supplies, audio equipment, renewable energy, industrial automation, and automotive electronics.

- How do I choose the right choke coil for my power supply?

- What are the advantages of ferrite vs. iron core choke coils?

- Where are common mode chokes required in industrial environments?

- What specifications should I consider when sourcing choke coils?

Benefits of Using Choke Coils

The use of choke coils offers multiple advantages in electronic circuit design. Beyond basic filtering, their inductive properties provide:

- Enhanced Signal Integrity: By blocking high-frequency noise, choke coils ensure cleaner power and data signals, which is crucial for high-speed digital and precision analog systems.

- EMI/RFI Compliance: Choke coils help electronic devices meet stringent electromagnetic compatibility (EMC) requirements, reducing the risk of interference with nearby equipment.

- Improved Reliability: By protecting components from voltage spikes, surges, and transients, choke coils extend the lifespan of electronic systems.

- Flexible Design Options: Available in various core materials, inductance values, and packaging formats, choke coils can be tailored to the specific needs of any application or industry.

- Cost-Effective Noise Suppression: Compared to more complex filtering solutions, choke coils offer an economical method for reducing noise and enhancing circuit performance.

- Thermal Stability: High-quality choke coils are designed to operate reliably in demanding environments, from industrial machinery to automotive and aerospace systems.

Key Specifications to Consider When Selecting Choke Coils

Are you evaluating choke coils for a new design or retrofit project? Consider these critical factors:

- Inductance (Henries): Determines the coil's filtering capability at specific frequencies.

- Current Rating (Amperes): The maximum continuous current the choke can handle without overheating.

- DC Resistance (Ohms): Lower resistance minimizes power loss and heating.

- Core Material: Ferrite, iron, and air cores offer different frequency responses and saturation characteristics.

- Saturation Current: The current at which the core material becomes magnetically saturated, affecting performance.

- Operating Temperature Range: Ensures reliable operation under expected environmental conditions.

- Mounting Style: Through-hole, surface-mount, or custom configurations for compatibility with your PCB layout.

- Size and Form Factor: Must fit within the physical constraints of your device or system.

- Compliance and Safety Certifications: UL, RoHS, REACH, and other standards may apply depending on your industry.

How to Choose Between Ferrite, Iron, and Air Core Choke Coils?

Selecting the right core material is essential for achieving optimal performance. Ferrite cores are ideal for high-frequency noise suppression, iron cores excel in low-frequency filtering with higher current handling, and air cores are preferred when linearity and low core losses are priorities—such as in RF circuits. Still unsure? Contact our experts for personalized recommendations based on your application requirements.

Choosing the Proper Choke Coil Supplier

Selecting a reliable choke coil manufacturer or supplier is vital to ensuring consistent performance and long-term reliability in your systems. With numerous suppliers offering a wide range of choke coil types, it's important to evaluate quality, technical expertise, and support.

- Product Range: Does the supplier offer the exact inductance, voltage, and current ratings your application requires?

- Customization Capabilities: Can they design or adapt choke coils for unique form factors, mounting requirements, or high-reliability environments?

- Quality Assurance: Look for suppliers with rigorous testing protocols and certifications such as ISO 9001, UL, or RoHS compliance.

- Technical Support: Reliable suppliers provide engineering assistance, datasheets, and application guidance for optimal selection and integration.

- Lead Times and Availability: Confirm inventory levels, standard production lead times, and options for expedited delivery.

- Reputation and Experience: Review supplier history, client testimonials, and case studies to gauge expertise and customer satisfaction.

To ensure a positive outcome when purchasing choke coils, compare several companies using our comprehensive directory of choke coil suppliers. Each business profile details their areas of expertise, product capabilities, and contact information. Use our patented website previewer to quickly assess each supplier's specialties, and submit a request for quote (RFQ) to multiple companies simultaneously for competitive pricing.

Ready to source choke coils for your project? Browse our directory to connect with top-rated manufacturers, request samples, or get a custom quote today.

Frequently Asked Questions About Choke Coils

What factors affect choke coil performance in high-frequency applications?

Core material, winding technique, and coil geometry all impact a choke coil's ability to suppress high-frequency noise. Ferrite beads and specialized winding patterns help reduce parasitic effects, ensuring efficient EMI filtering in RF and data circuits.

How do I calculate the required inductance for my application?

The required inductance depends on your circuit's frequency, the level of attenuation needed, and current requirements. Use standard filter design equations or consult with a choke coil specialist for optimal sizing and integration.

Can I use the same choke coil for both AC and DC circuits?

While choke coils pass DC and block AC, it's important to select a coil rated for the expected current, voltage, and frequency range. Consult datasheets to verify compatibility before installation.

What is the difference between differential mode and common mode chokes?

Differential mode chokes filter out noise present between two conductors, while common mode chokes attenuate noise common to both lines. The choice depends on the type of interference present in your application.

How can I test the performance of a choke coil?

Use an LCR meter to measure inductance and resistance, and an oscilloscope to evaluate filtering effectiveness under real-world operating conditions. Many suppliers offer test data and typical performance curves for reference.

Choke Coils: Empowering Reliable and Efficient Electronic Systems

In summary, choke coils are indispensable components for engineers and designers seeking to optimize power quality, suppress electromagnetic interference, and ensure robust signal integrity. Whether you are developing consumer electronics, industrial automation systems, renewable energy solutions, or automotive electronics, selecting the right choke coil is key to achieving regulatory compliance, efficiency, and long-term reliability.

For more in-depth technical guidance, application support, or to request a quote from leading choke coil manufacturers, explore our supplier directory or reach out to our team of experts for personalized assistance.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services