Motor coils are an essential component in electric motors, driving the mechanical motion that powers countless machines and devices. Whether it’s the familiar hum of a ceiling fan, the precise movements of industrial machinery, or the immersive sound of a speaker, motor coils play a vital role in converting electrical energy into mechanical force. Read More…

We are proud of the craftsmanship of our engineers. All of our products are made right here in the United States and we promise that these items are created from high quality resources. Our electrical coils are unique and efficient.

Established in 1973, Classic Coil Company is a Contract Manufacturer of electronic coils. We manufacture coils for a variety of industries; winding wire gauges from 4-58 AWG. We are ISO 9001-2015 certified, ITAR registered and DFARS Compliant. Our Engineering services allow us to assist with design, reduce cost, and increase efficiency in production. Call or visit our website to learn more about...

Since 1962, Torelco has been a supplier of electric coils and transformers of superior quality. We offer custom coils, solenoid coils, ferrite core coils & toroid wound coils to serve a range of industries. Markets served include medical, military, electronics, and industrial. When you work with us, our promise is to build to the exact specifications and meet the custom needs of our customers.

Check out what’s new online at Precision Econowind, manufacturer of the highest quality custom coils at reasonable prices, with on time delivery. Serving the coil industry for over 30 years, we’re experienced with producing loudspeaker & medical industry coils, coils wound on customers’ bobbins/tooling; freestanding, flat wire, edge wound, square, rectangle & shaped coils. Submit your specs ...

Triad Magnetics has been in the electric coils industry for over 75 years. Giving us the knowledge and expertise to be one of the best in the industry. We have a wide range of electric coils and inductors as well as the ability to custom engineer and manufacture electric coils to our customer’s needs. Having served the needs of many industries for more than half a century, Triad believes its...

More Motor Coil Manufacturers

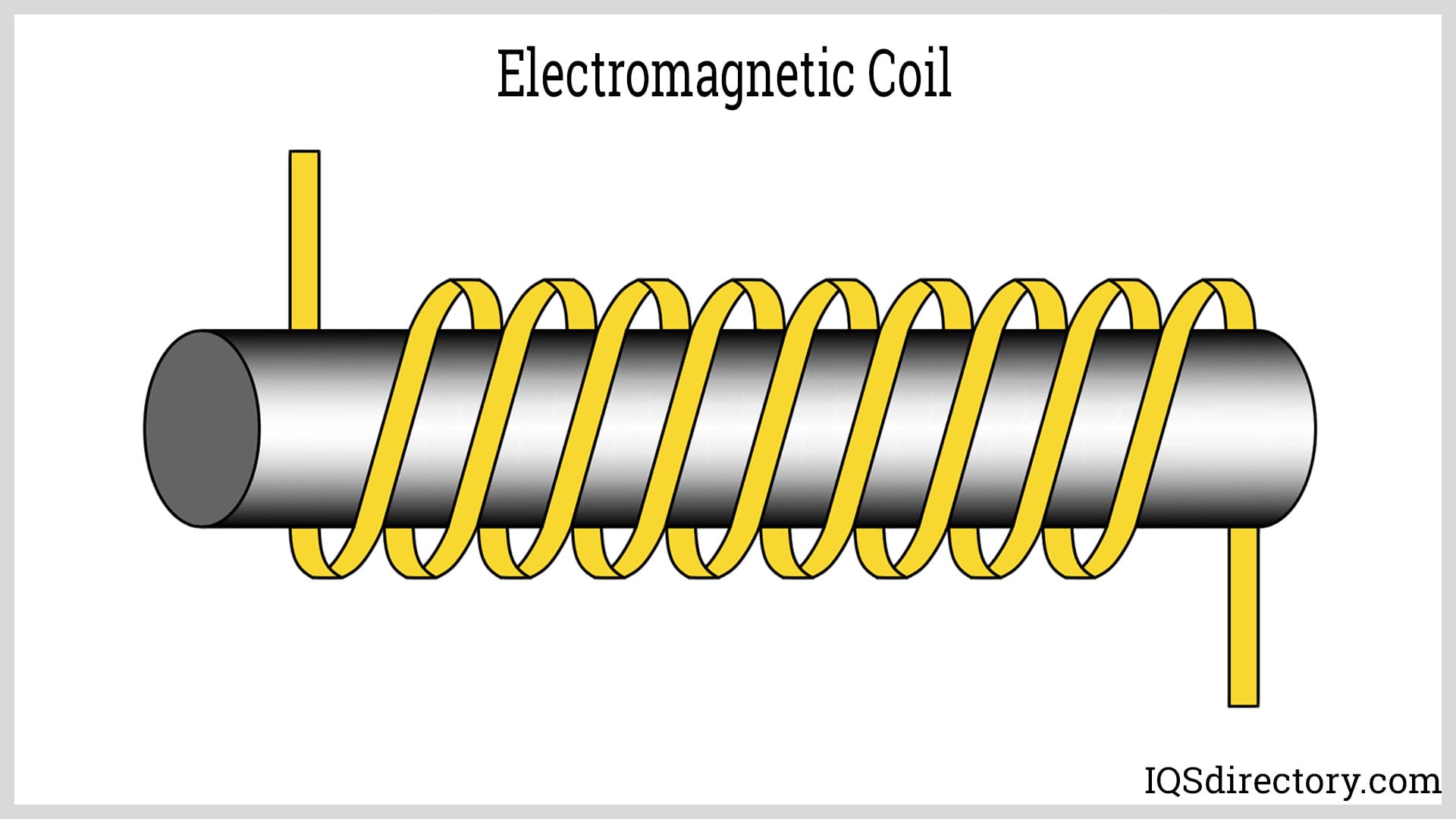

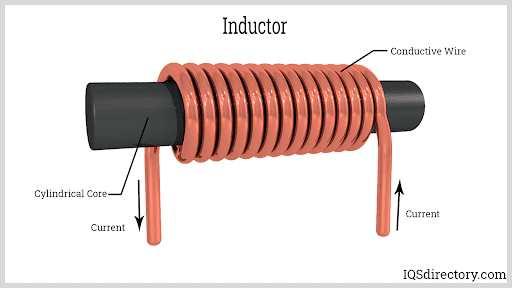

Components of Motor Coils

Motor coils consist of several key components that work in unison to produce the desired motion. The primary component is the wire, typically made of copper or aluminum, which carries the electrical current. The wire's characteristics, such as gauge and insulation type, impact the coil's performance. The core, often made of ferromagnetic materials like iron or steel, concentrates the magnetic field generated by the coil, enhancing its efficiency. Insulation is crucial to prevent electrical short circuits and ensure safe operation. Lastly, terminal ends provide the connection points for the coil to receive electrical power.

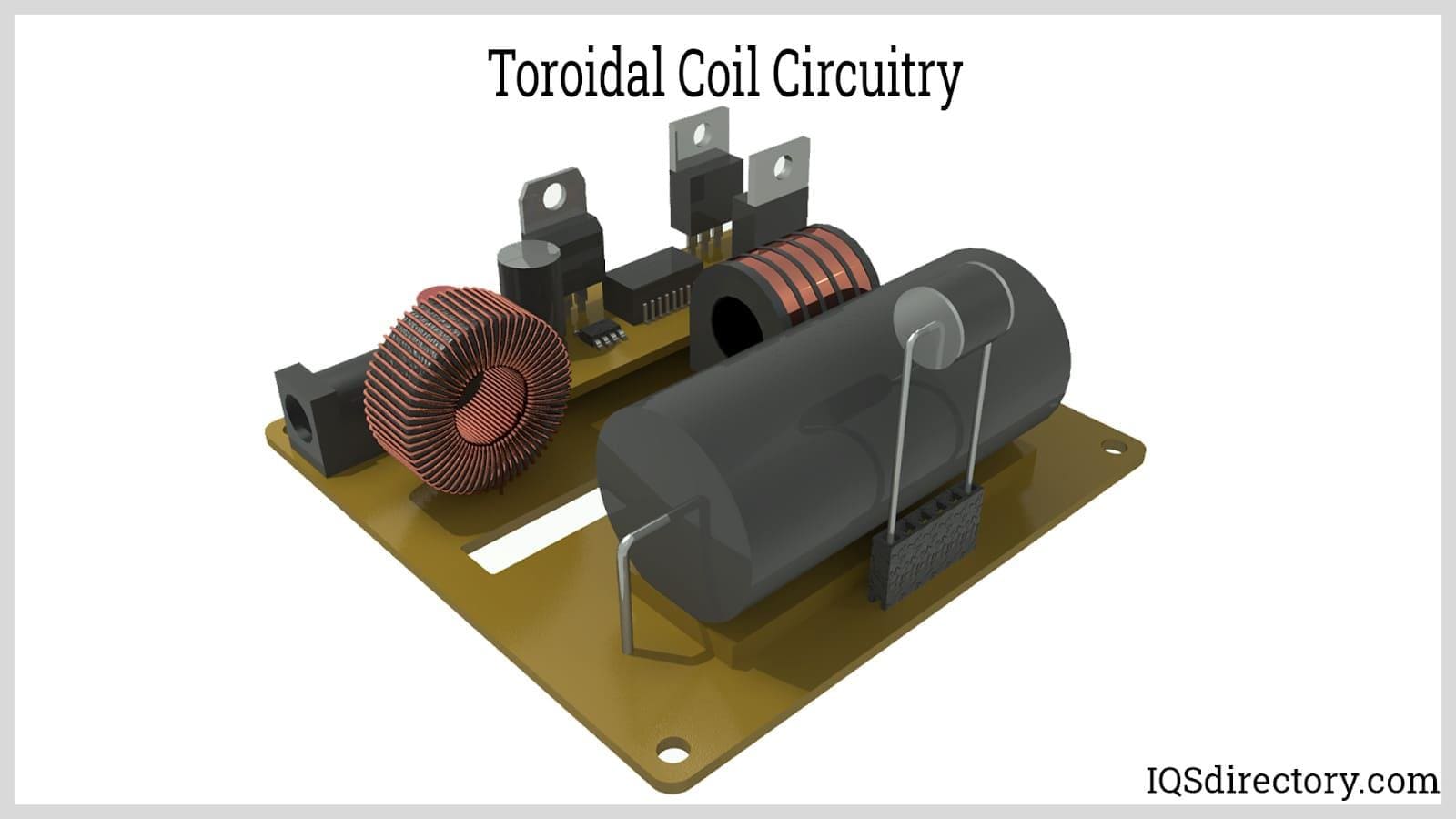

Variations of Motor Coils

Motor coils come in various forms, each tailored to specific applications. Single-phase motor coils are commonly found in ceiling fans, where they enable the smooth rotation of the blades. Three-phase motor coils are prevalent in industrial machinery, powering complex manufacturing processes with their robust and reliable performance. Voice coil motor coils, meanwhile, are utilized in loudspeakers, delivering precise and responsive sound reproduction. Linear motor coils, on the other hand, find their place in magnetic levitation systems, where they enable stable and controlled movement in a straight line.

Materials Used for Motor Coils

Different materials are employed in motor coils based on their unique properties and application requirements. Copper is a popular choice due to its excellent conductivity and high melting point, making it ideal for demanding applications such as electric vehicles, where efficiency and power are paramount. Aluminum, known for its lightweight and cost-effectiveness, finds its application in HVAC systems, where motors need to be energy-efficient while maintaining cooling capabilities. Additionally, superconducting materials are utilized in specialized cases, such as magnetic resonance imaging (MRI) machines, where low resistance and powerful magnetic fields are essential for precise imaging.

Considerations Regarding Motor Coils

While motor coils offer numerous advantages, there are some considerations to bear in mind. Heat dissipation can pose challenges, especially in high-performance applications, where excessive heat can reduce efficiency and potentially damage the motor. Additionally, coil resistance can lead to power loss, which affects overall motor performance and energy efficiency. However, advancements in design and materials have addressed many of these concerns, ensuring improved performance and reliability.

Benefits of Motor Coils

Motor coils offer a wide array of benefits that make them indispensable in various applications.to begin with, their high efficiency allows for effective conversion of electrical energy into mechanical force, minimizing wasted power and maximizing overall performance. This efficiency translates to energy savings, reduced operating costs, and increased sustainability. Additionally, motor coils have a compact design, making them suitable for integration into space-constrained systems or devices. Their small footprint optimizes the use of available space while maintaining high power output. Furthermore, motor coils provide precise control over the generated force, enabling accurate and responsive movement. This attribute is crucial in applications where precision and fine-tuned operation are paramount, such as robotics, automation, and medical equipment. Moreover, motor coils exhibit excellent reliability and durability, ensuring long-term operation with minimal maintenance requirements. Their robust construction and carefully selected materials contribute to their ability to withstand harsh operating conditions and extended use. Overall, the benefits of motor coils encompass enhanced efficiency, compact design, precise control, reliability, and longevity, making them indispensable in a wide range of industries and applications.

Choosing the Appropriate Motor Coil for Your Application

Selecting the right motor coil for your application involves considering several key factors. First, determine the power requirements, including voltage and current specifications, to choose a coil with the appropriate wire gauge and insulation. Next, assess the environmental conditions to ensure the coil can withstand factors like temperature, humidity, and vibrations. Then, evaluate the speed and torque demands of your application and select a coil design and materials accordingly. Consider physical constraints, such as space limitations or mounting requirements. Seeking expert advice from motor coil manufacturers can also provide valuable insights tailored to your specific needs. By carefully considering these factors, you can make an informed decision and ensure optimal performance, efficiency, and reliability for your application.

Applications of Motor Coils

The applications of motor coils span a vast range of industries and sectors. Electric vehicles, for instance, rely on motor coils to drive their wheels, providing sustainable and efficient transportation solutions. In robotics, meanwhile, motor coils enable the intricate movements required for delicate and complex tasks. The aerospace industry also utilizes motor coils in systems ranging from flight control surfaces to satellite deployment mechanisms. HVAC systems additionally utilize motor coils to power fans and compressors, ensuring efficient climate control in buildings. Even consumer electronics, such as smartphones and laptops, utilize miniature motor coils for vibration feedback and precise motorized components.

Motor coils also have applications across many more industries. In automation, for example, motor coils power robotic arms, conveyor belts, and automated manufacturing processes, enabling precise and efficient movement and control. Medical equipment also heavily relies on motor coils for applications such as medical imaging systems, robotic surgical devices, and prosthetics. Motor coils in medical equipment ensure accurate and reliable performance, facilitating diagnostics, treatment, and rehabilitation processes. In the realm of audio technology, motor coils are utilized in loudspeakers, providing the necessary magnetic field for precise cone movement and generating high-quality sound reproduction. Finally, in industrial machinery, motor coils drive heavy-duty equipment, such as pumps, compressors, and conveyor systems, delivering robust and reliable performance in demanding manufacturing environments.

Choosing the Right Motor Coil Supplier

To ensure you have the most beneficial outcome when purchasing motor coils from a motor coil supplier, it is important to compare several companies using our directory of motor coil suppliers. Each motor coil supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each motor coil business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple motor coil companies with the same form.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services